Pusher

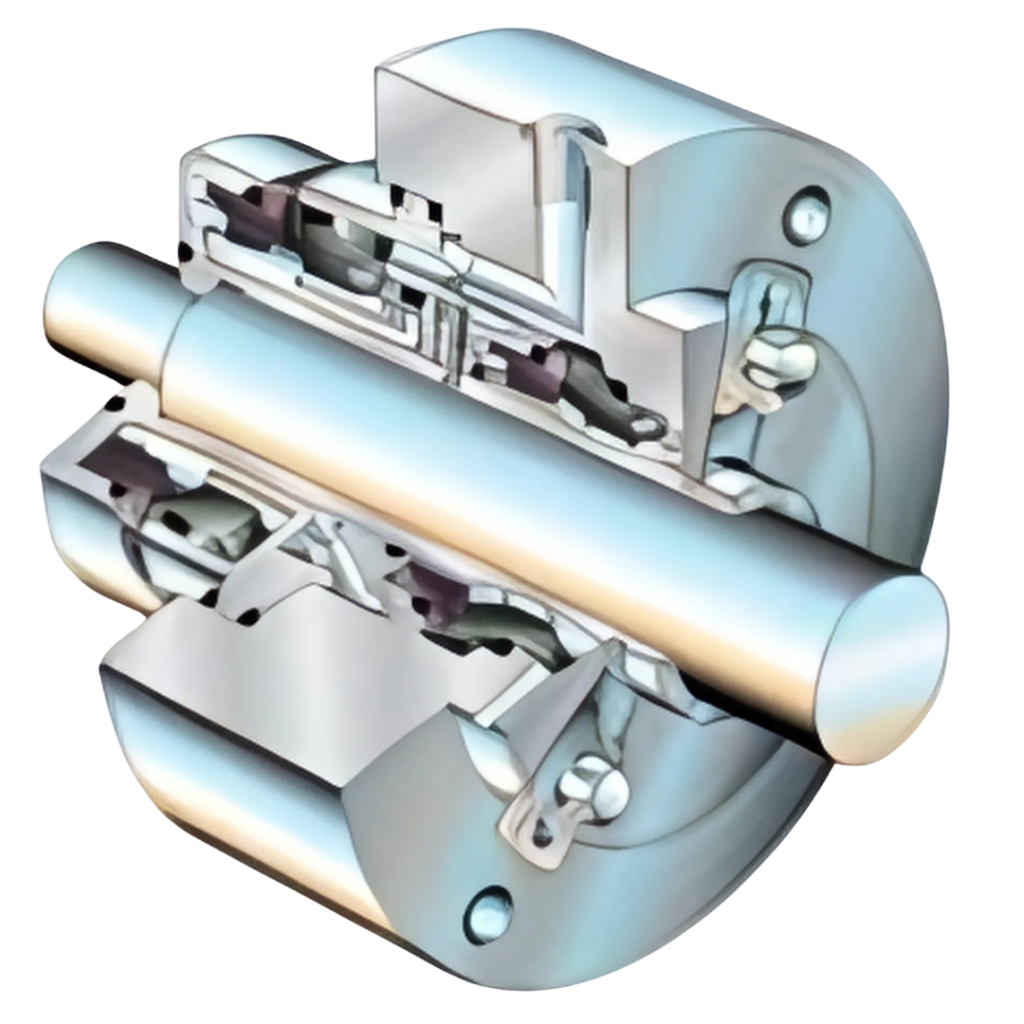

Flowserve Pac-Seal Specialty Mechanical Seal

Flowserve Pac-Seal Specialty Mechanical Seal

| Brand | Pac-Seal |

|---|---|

| Description | Flowserve Pac-Seal elastomeric bellows component seals are engineered for diverse applications, combining precision design with high-performance materials. Using advanced engineering analysis, these mechanical seals offer exceptional reliability and are built to meet demanding industry standards. Pac-Seal technology leverages Flowserve’s deep expertise in elastomers, plastics, exotic alloys and sealing materials to reduce maintenance, extend service life and lower total cost of ownership. |

Pac-Seal Key Features

-

Crimped-head rotary unit simplifies installation and eliminates metal-to-seal contact

-

Hex-torque drive evenly distributes drive load across the seal’s outer shell for improved life

-

Supports a wide range of pressures and temperatures

-

Designed for stability, efficiency and minimal maintenance

-

Broad range of configurations available for light, medium and heavy-duty use

Pac-Seal Specifications

| Parameter | Value |

|---|---|

| Pressure | Up to 27 bar (400 psi) |

| Speed | Up to 25 m/s (82 fps) |

| Temperature | -40 to 205°C (-40 to 400°F) |

Pac-Seal Configurations

-

ASP: Advanced stationary pusher

-

ARB: Advanced rotating bellows

-

Type 16: Light duty rotating bellows

-

Type 68: Light duty stationary compression unit

-

Type 21: Medium duty rotating bellows

-

Type 31: Medium duty rotating bellows, hard faces

-

Type 51: Narrow cross-section rotating bellows

-

Type 52: Short length narrow cross-section rotating bellows

-

Type 8: Heavy duty, multi-spring rotating compression unit

Pac-Seal Industries

Power, Nuclear, Steam, Combined Cycle, CSP, Biomass, Geothermal, Chemicals, Biofuels, Pharmaceuticals, Petrochemicals, Water Management, Wastewater, Irrigation, Flood Control, Oil and Gas (Upstream, Midstream, Downstream), General Industries, Pulp & Paper, Steel, Food & Beverage, Ethanol, Mining

Pac-Seal™ Mechanical Seals – Brochure

Pac-Seal ASP-X Installation Instructions

Pac-Seal Type 68 Installation Instructions

Pac-Seal Type 8/8T Installation Instructions

Looking for a versatile and proven mechanical seal solution? Contact us today to find the right Flowserve Pac-Seal configuration for your specific industrial process.

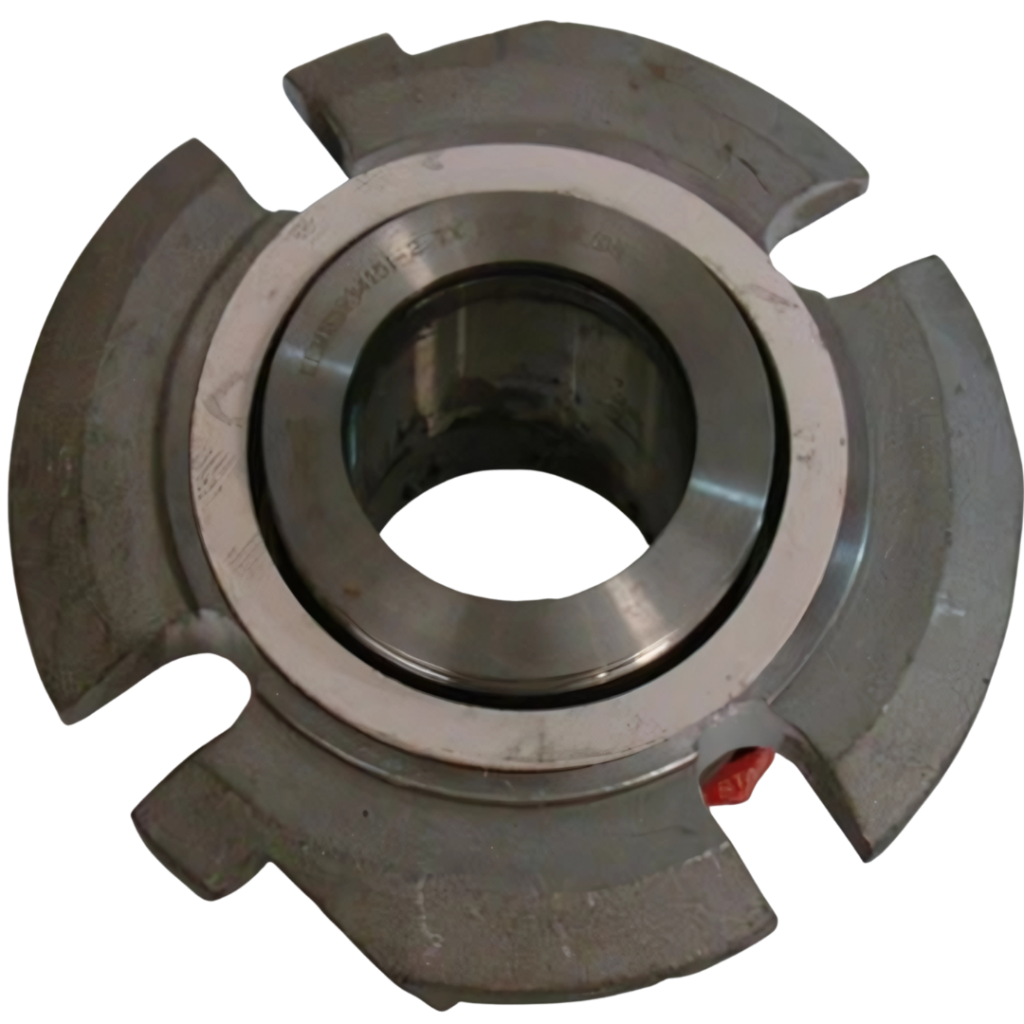

QB 61 Pusher Seal

QB 61 Pusher Seal

NSF International has rigorously tested and evaluated the QB 61 pusher seal, and it is NSF/ANSI/CAN 61 & 372 certified for drinking water applications from source to tap. The NSF certifications include all wetted components of the seal and show how QB 61 seals exceed regulatory criteria for drinking water quality, giving municipalities confidence in seal selection and operation.

QB 61 Pusher Seal for Water and Industrial Applications

Benefit

- Improve water quality with NSF/ANSI/CAN 61 certified products that meet demanding industry and regulatory criteria.

- Third-party, unbiased review from a well-known certifying agency.

- Product quality and consistency supported by regular NSF inspections and testing to keep certification.

- Advanced spring holder design including radial apertures for recirculation and self-cleaning at both end of the springs.

- Big cross-section seal faces designed for maximum variety of use.

- Solid drive keys effectively convey torque stresses from the seal face without distortion.

Specification

Standards: NSF/ANSI/CAN 61 & 372

Size Range: 22.2 to 168.2 mm (0.875 – 6.625 in)

Operating Parameters

- Pressure: up to 51.7 bar (750 psi)

- Temperature: -40° to 204°C (-40°F to 400°F)

- Speed: up to 23 m/s (75 fps)

Certified materials and sizes

- Metal parts: 316 stainless steel

- Seal faces: Reaction bonded silicon carbide vs. reaction bonded silicon carbide, premium resin carbon vs. reaction bonded silicon carbide

- Gaskets: Fluoroelastomer

- Sizes: 22 to 168 mm (0.875 to 6.625 in.)

Related Industries

- Water

- Water Management

- Wastewater

- Agriculture & Irrigation

- Flood Control System

- Desalination

- QB-61 NSF/ANSI/CAN 61 Certified Standard Cartridge Seals for Drinking Water Applications

- QB Series Balanced Pusher Seals – Brochure

- Mechanical Seal Guidelines for Wastewater Treatment

- Seals Designed for All Fluid Management Challenges Brochure

Enhance your sealing solutions with the QB 61 Pusher Seal. Contact us today to learn how it can improve performance in your water and industrial applications.

Flowserve QB Pusher Seal

| Brand | Flowserve |

|---|---|

| Description | Flowserve’s QB Series Pusher Seals are high-performance balanced mechanical seals available in both single and dual configurations. Designed to meet API 682 Type A standards, these seals are ideal for environmentally-sensitive and hazardous applications, providing superior sealing, enhanced cooling, and longer service life even in the most demanding operating conditions. |

QB Series Key Features

-

Rugged, reliable cartridge design with robust components and seal faces

-

API 682 compliant for single and dual arrangements

-

Multiport injection enables superior face cooling and minimal distortion

-

Dual seal configurations enhance environmental protection and emission control

-

Maintains performance under upset conditions with low vapor pressure margin

-

Clog-resistant spring design (QBS) suited for dirty applications

-

QBU handles low-lubricity hot water without auxiliary cooling

-

QBQ designed for vaporizing hydrocarbon services

-

QBQ LZ features Precision Face Topography for improved sealing under low vapor pressure

-

QBB and QB2B configurations support a wide range of pressure and piping plans

-

Available with fixed, floating, or segmented throttle bushing designs

QB Series Specifications

| Parameter | Value |

|---|---|

| Compliance | API 682 Type A |

| Pressure | Up to 51.7 bar (750 psi) |

| Temperature | -40 to 204°C (-40 to 400°F) |

| Speed | Up to 23 m/s (75 fps) |

| Size Range | 12.7 to 139.7 mm (0.500 to 5.500 inch) |

QB Seal Configurations

-

Arrangement 1 (Single Seal) – Plans 11, 13, 23, 32, 62

QB, QBQ, QBS, QBU -

Arrangement 2 (Unpressurized Dual Wet Seal) – Plan 52

QB/QB, QBQ/QBQ, QBQ LZ/QBQ -

Arrangement 2 (Dry Backup) – Plans 72, 75, 76

QBQ/GSL, QBQ LZ/GSL -

Arrangement 3 (Pressurized Dual Wet Seal) – Plans 53A, 53B, 53C, 54

QBB/QB, QB2B/QB

Industries Served

- Power – Nuclear, Conventional Steam, Combined Cycle, Biomass

- Chemicals – Basic & Inorganic

- Oil & Gas – Downstream Processing

- Water – Water Management, Desalination

QB Series Balanced Pusher Seals – Brochure

Looking for a high-reliability pusher seal for sensitive applications? Contact us today to learn how the Flowserve QB Series can enhance uptime and ensure environmental compliance.

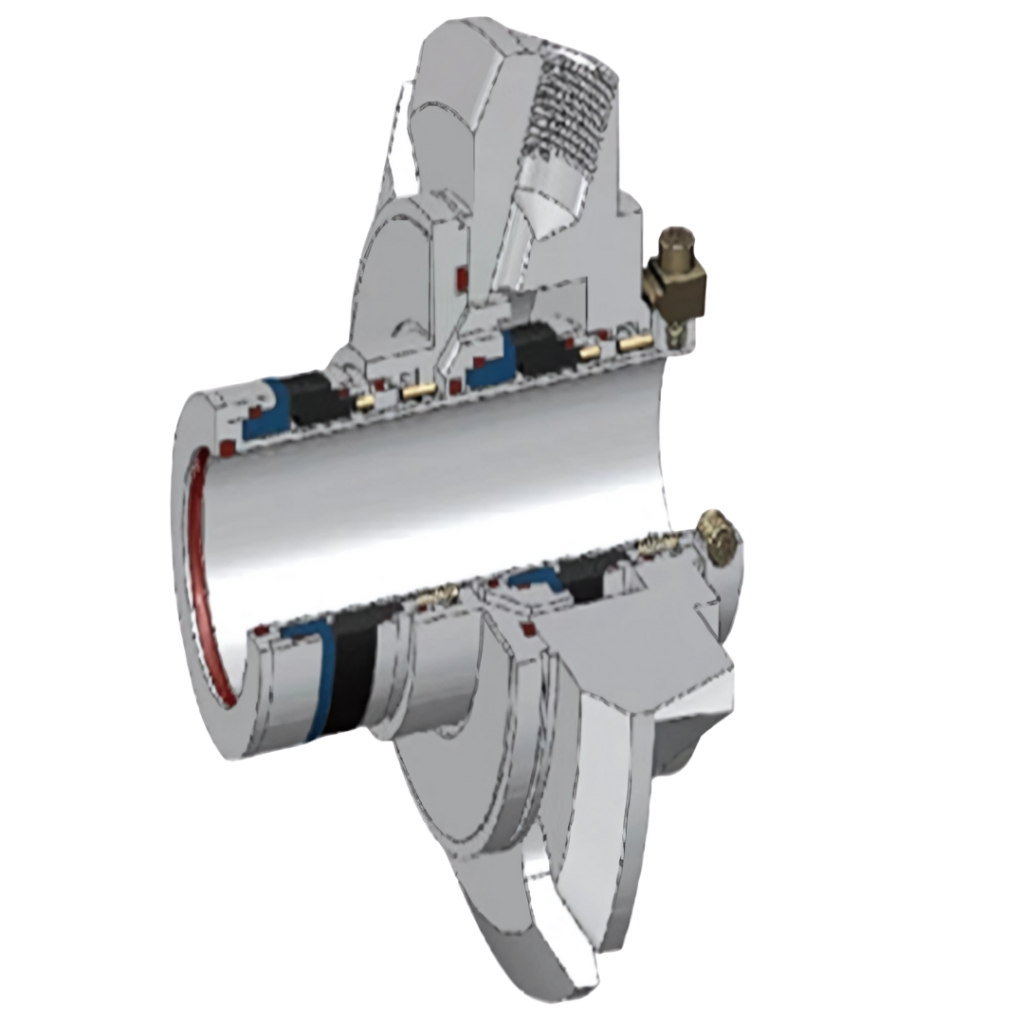

Flowserve ISC2 Series Cartridge Seals

Flowserve ISC2 Series Cartridge Seals

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve ISC2 Series is a comprehensive family of standardized cartridge seals engineered for maximum reliability, flexibility and interoperability across a wide range of pump models and applications. Built to meet API 682, ASME (ANSI), DIN 24960 and ISO standards, ISC2 seals are ideal for facilities seeking to reduce inventory, streamline maintenance and improve uptime across multiple systems. From general-purpose to toxic and high-demand services, ISC2 seals are designed to last, even under dry running, frequent cycling, and off-design conditions. |

ISC2 Applications and Industries

Applications:

-

Pipeline

-

Power Generation

-

Pulp and Paper

-

Agricultural Chemicals

-

Synthetic Production

-

Bioprocessing

-

Tank Farm Transfer

-

Chemical Processing

-

Toxic Services

-

Wastewater and Condensate

-

Light Oils and Slurries

-

Organic and Inorganic Chemicals

-

Petrochemical and Hydrocarbon Processing

Industries Served:

-

Agriculture

-

Chemical and Liquor

-

Tank Farms and Logistics

-

Pharmaceuticals

-

Paper Stock and Pulp

-

Pipeline Products

-

General Industrial Applications

Key Features and Benefits

-

Full API 682 compliance for industry-standard performance

-

Robust face drive mechanism improves reliability during variable operation

-

Dry-run capable thermal management increases seal longevity

-

High-efficiency barrier fluid circulation for enhanced cooling

-

Rigid setting devices ensure consistent installation

-

Standardization across multiple equipment types minimizes spare parts inventory

-

Multiple configurations: Single, Dual, Pusher, and Metal Bellows

-

Ideal for high cycling and stop-start systems

Standardize your operations with industry-leading reliability. The Flowserve ISC2 Series is the smart choice for engineers and operators seeking dependable mechanical sealing solutions across general and mission-critical applications. Contact us today for product recommendations, API compliance consultation or to request a datasheet, our experts are ready to assist your sealing system needs.

Flowserve CRO Pusher Seal

Flowserve’s CRO Pusher Seal is an affordable Pusher Seal featuring a friction drive design with a single coil spring, specifically engineered for use in ANSI chemical pumps with packing box seal chambers. The heavy cross-section and minimal number of components simplify installation and enhance resistance to severe corrosion. With no wetted metals and a shared spring in the double CRO Pusher Seal design, it ensures reliable performance. The Mechanical Seals in the CRO design are readily available off the shelf in standard configurations, making them ideal for a wide range of popular chemical pumps in the market today.

-

Features

- Rotating Seal Ring – Self centers around the shaft. Designed to withstand the harsh physical demands of cyclic operation or continuous duty. Available in a wide range of standard materials.

- Single Coil Spring – Robust spring resists clogging and chemical attack. CRO-P option adds positive rotor drive through a drive collar and pin arrangement.

- Shaft Packing – completely interchangeable materials without changing other components. Available in a wide range of materials for compatibility with process fluids and process temperatures.

- Stationary Insert – Flexibly mounted to precent distortion

- O-Rings – Dimensionally interchangeable for versatility in secondary seal materials selections.

CRO Mechanical Seals Operating Parameters

Pressure Up to 200 bar (300 psi) Temperature CRO: – 40 to 49°C (-40 to 120°F) CRO-P: -40 to 260°C (-40 to 500°F)

Shaft Speed Up to 23 m/s (75 fps) Shaft Sizes 9.5 to 89 mm (0.375 to 3.500 inch) Materials of Construction

Metal Components 316 Stainless Steel, Allot C-276, 20 Stainless Steel Rotating Face Tungsten Carbide, Silicon Carbide, Peramic, Durchorme® Stationary Face Tungsten Carbide, Silicon Carbide, Bronze, Resin Carbon Spring 304, 316, or 20 Stainless Steel, Alloy C-276 or B-2, XM-19 or 17-7 PH Stainless Steel, Titanium, Alloy 400 Gaskets Fluoroelatomer, Buna N, EPDM, Rubber (EPR), Perfluoroelatomer, Neoprene, PTFE

CRO Durametallic Seals Industrial Applications

- General Applications

- Pulp & Paper

- Mining

- Steel & Primary Metals

- Food & Beverage

- Corn Wet Milling & Ethanol

- Other Industries

- Chemicals

- Basic (Organic & Inorganic)

- Specialty (Fine & Consumer)

- Biofuels

- Pharmaceutical

- Water

- Water Management

- Wastewater

- Agriculture & Irrigation

- Flood Control System

- Power

- Conventional Steam

- Geothermal

- Combined Cycle

- Concentrated Solar Power (CSP)

- Biomass & MSW

Configurations

|

|

| CRO | Double CRO |

Flowserve Allpac N – DIN 24960 Form C Balanced Mechanical Seal

Flowserve Allpac N – DIN 24960 Form C Balanced Mechanical Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve Allpac N is a wavy spring mechanical seal cartridge engineered for DIN 24960 Form C compatibility. Available in single, double, or tandem configurations, the Allpac N is designed specifically for challenging services such as slurry transfer, acid handling, and chemical processing. Each seal pair utilizes two 100% identical seal faces, ensuring long-term sealing symmetry and wear balance. In double seal configuration, the inboard seal is reverse pressurized, greatly enhancing resistance to clogging and ensuring reliable operation in slurry-laden or viscous environments. The seal is available only in four standard DIN sizes, making it a precise fit for applications using DIN Form C metric equipment. |

Applications and Industries

Industries Served:

-

Slurry Transfer & Processing

-

Primary and Mineral Processing

-

Polymers and Pharmaceuticals

-

Acid Transfer and Leaching

-

Caustic and Chlor-Alkali Systems

-

Solvent and VOC Handling

-

Dewatering and Water Supply

-

Auxiliary and Utility Systems

-

Waste Processing

Key Features and Benefits

-

Compliant with DIN 24960 Form C specifications

-

Available in single, tandem, or double balanced cartridge configurations

-

Wavy spring design offers robust seal face loading in variable operating conditions

-

100% identical seal face pairs improve performance and wear distribution

-

Reverse pressurized inboard seal (in double configuration) resists clogging in slurry applications

-

Designed for metric DIN Form C pumps – available in four standard sizes

-

Easy installation and maintenance in cartridge format

General Installation and Maintenance Instructions

Need a reliable DIN 24960 Form C seal for slurry or chemical applications? The Flowserve Allpac N delivers durable, clog-resistant sealing in single, tandem, or double balanced configurations, perfect for process-critical operations involving slurries, acids or VOCs. Contact us today to request sizing info, datasheets or a quotation tailored to your equipment and media.

Flowserve QB Mechanical Seal

Flowserve QB Mechanical Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve QB is a single, balanced, multi-spring pusher mechanical seal engineered for general service in the chemical and petrochemical industries. Fully compliant with API 682 Type A specifications, this seal delivers dependable performance across a wide range of standard and demanding applications. Its modular design allows for variations to suit different pressures, temperatures, and fluid properties, reducing emissions, improving safety and increasing equipment reliability. |

Flowserve QB Mechanical Seal Key Features and Benefits

-

Balanced, multi-spring pusher seal for general service

-

Designed for API 682 Type A applications

-

Available in multiple configurations:

-

QBQ: High balanced, low emission seal for light hydrocarbons

-

QBB: Dual balanced option for reverse pressure (API 682 Arrangement 3)

-

QBU: Lubricated hot water design (up to 255 psi, 170°C)

-

QBR: Reverse configuration with stationary flexible element

-

QBQ/GSL: Dual seal with dry-running containment backup

-

-

High reliability in high-speed and low-specific-gravity applications

Industries Served

-

Petrochemical

-

Chemical processing

-

Pharmaceuticals

-

Waste processing

-

Utilities and power

-

Crude oil and heavy oil upgrading

-

Water injection and treatment

-

VOCs, alkylation, hydrotreating, delayed coking, catalytic cracking

Typical Applications

-

Light hydrocarbon transfer

-

Hot water pumping

-

General-purpose fluid handling

-

API 682-compliant pump systems

QB Seal Installation InstructionsContact our engineering team today to select the right QB seal configuration for your pump system. Whether you need enhanced emissions control, reverse pressure capability or high-temperature resistance, our experts are ready to help.

Flowserve Europac 600 Series Seals

Flowserve Europac 600 Series Seals

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve Europac 600 series is a family of mechanical seals engineered to comply with the DIN 24960 standard, primarily for use with DIN standard chemical pumps. Designed for reliable sealing in corrosive and volatile fluid handling, these seals are ideal for pharmaceutical, chemical and waste processing industries. |

Series Overview

-

Europac 600:

Unbalanced, single wavy spring pusher seal for general chemical duties -

Europac 610:

Balanced version requiring a stepped shaft for higher pressure (up to 25 bar) -

Europac 615-Lube:

Balanced hot-water service design with lube groove face, no external cooling required (up to 17.5 bar, 170°C)

Europac 600 Series Seals Key Features

-

Conforms to DIN 24960 (L1k)

-

Compact design with wavy spring configuration

-

Compatible with DIN standard pumps

-

Seal face options include:

-

B: Resin-impregnated carbon

-

A: Antimony-impregnated carbon

-

S: Chrome steel

-

Q: Sintered silicon carbide

-

-

Suitable for corrosive, high-temperature, and chemically aggressive environments

Common Applications

-

Acid and solvent transfer

-

VOC containment

-

Caustic chemical handling

-

Slurry and polymer processing

-

Waste and auxiliary systems

-

Pharmaceutical production systems

Industries Served

Flowserve Seals – Products and Services Catalog – English

Need a seal that complies with DIN 24960? Europac 600 series is your solution. Whether you require high-pressure resistance or thermal tolerance, Flowserve offers reliable configurations for demanding chemical applications. Contact Us.

Flowserve RO Series Mechanical Seals

Flowserve RO Series Mechanical Seals

| Brand | Flowserve |

|---|---|

| Description |

Discover the complete range of Flowserve mechanical seals including bellows, cartridge, pusher and elastomer designs, engineered for superior performance in chemical processing, water treatment, petrochemical, slurry and general industrial applications. Designed in compliance with API 682, DIN24960 and ANSI standards, these seals deliver leak protection, reliability and minimal maintenance. |

Featured Seal Models

QB Series – Balanced General Service Pusher Seal

-

Multi-spring, single balanced pusher seal

-

Complies with API 682 Type A

-

Options include:

-

QBQ – High-balanced for light hydrocarbons

-

QBB – Dual balanced reverse pressure configuration

-

QBU – Lube-groove design for hot water without cooling

-

QBR – Stationary flexible element

-

QBQ/GSL – Dual seal with dry containment for safety

-

RO Series – ANSI Chemical Pump Seal

-

Simple, open rotary design resists clogging

-

Designed for aggressive, abrasive, and viscous media

-

Preferred by maintenance teams for standard ANSI pumps

Europac 600 Series – Wavy Spring Seal

-

Single unbalanced seal per DIN 24960 (L1k)

-

Common in DIN chemical pumps

-

Available options:

-

Europac 610 – Balanced variant for stepped shafts

-

Europac 615-lube – With lube grooves for hot water service

-

BXR Series – Stationary Metal Bellows Seal

-

API 682 compliant

-

Handles high-speed and corrosive media

-

Stationary bellows tolerate misalignment and reduce wear

BXHHS Series – High-Temperature Bellows Seal

-

Welded Alloy 718 rotating bellows

-

Shrink-fit stationary face

-

Ideal for high-temperature petrochemical applications

-

API 682 Type C compliant

X-100 Series – Single Cartridge Bellows Seal

-

Welded bellows in cartridge form

-

Compatible with ANSI and DIN chemical pumps

-

Alloy C-276 bellows for harsh media

-

Optional throttle bushing available

X-200 Series – Dual Cartridge Bellows Seal

-

Dual rotating bellows

-

Pressurized or unpressurized operation

-

Built-in flow inducer for cooling

-

Same gland as X-100, suitable for standard chemical pumps

Allpac N Series – DIN Cartridge Seal

-

Wavy spring seal in single, tandem, or double configuration

-

DIN 24960 Form C compliant

-

Reverse pressurized inboard face for clog resistance

ISC1EX and ISC2BB – Elastomer and Bellows Cartridges

-

ISC1EX: Single elastomer bellows with Pac-Seal tech

-

ISC2BB: Dual bellows cartridge with Alloy C-276

-

Both fit ANSI and DIN standard chemical pumps

GTS Series – Steam Turbine Seal

-

Single wavy face for non-contact steam service

-

Operates on steam, hot condensate, or water-steam mix

-

Available in integral or detachable configurations

-

Bi-directional wavy face reduces install error

RO Series Mechanical Seals Applications and Industries

-

Chemical and Petrochemical Processing

-

Water and Wastewater Treatment

-

Refinery, Oil and Gas

-

Food and Beverage

-

Slurry and Mining

-

Power Generation and Utilities

-

Desalination and Boiler Feed

-

Snowmaking and Fire Protection

Why Choose Flowserve Seals

-

Full compliance with international standards (API, ANSI, DIN)

-

Wide material selection: Alloy C-276, Alloy 718, Carbon, SiC

-

Off-the-shelf availability for major chemical pump brands

-

Engineered for low emissions, long life, and minimal maintenance

Flowserve Seals – Products and Services Catalog – English

Double CRO Installation Instructions

Single Inside Pusher Seal Installation Instructions

Need help selecting the right Flowserve seal for your application? Our team is ready to assist with seal sizing, material selection, and application engineering. Get in touch with us today to request a quote or technical consultation.

Flowserve SL 5000 and SL 5200 Slurry Cartridge Seals

Flowserve SL 5000 and SL 5200 Slurry Cartridge Seals

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve SL 5000 and SL 5200 are cartridge-type mechanical seals engineered for pulp, paper, and slurry handling applications. These multi-spring, balanced pusher seals are built to withstand abrasive and demanding service conditions while simplifying installation and extending seal life. |

SL 5000 and SL 5200 Slurry Cartridge Seals Features

-

SL 5000: Single, balanced, multi-spring cartridge pusher seal

-

SL 5200: Double back-to-back configuration with identical inboard and outboard faces

-

Designed for slurry services in pulp and paper industries

-

Seal faces are fully exposed to the pumped media for optimal heat dissipation

-

Special shroud protects springs and drive pins from slurry buildup

-

No need for external flush liquid, reducing product dilution

-

Pre-set cartridge design with centering tabs for easy installation

SL 5000 and SL 5200 Slurry Cartridge Seals Applications

These seals are suitable for a wide range of industries, including:

-

Waste processing

-

Water treatment and desalination

-

Chemical and liquor handling

-

Paper and pulp processing

-

Food and beverage production

-

Acid and caustic transfer

-

Mining and slurry processing

-

Automotive and industrial machinery

-

Electronics and plating

-

Agriculture, irrigation, and snowmaking

-

Flood control and firefighting systems

SL-5000/5200 Cartridge Slurry Seals Installation InstructionsNot sure which Flowserve seal fits your application? With options from single pusher to dual bellows and DIN-compliant designs, we can help you select the right mechanical seal for your pump, process and industry needs. Reach out to our team today for technical guidance, documentation and a fast quotation.

Allpac Slurry Pusher Seals

Allpac Slurry Pusher Seals

| Brand | Flowserve |

|---|---|

| Description |

This is Flowserve’s Corrosive duty seals. Provides economic seal life – low operating and maintenance costs. A single, dual balanced robust yet simple slurry with low operation and maintenance costs. |

Internally mounted, double balanced, single mechanical seal, available in two versions:

- Balanced, closing from the product side (Allpac 480)

- Unbalanced, closing from the atmospheric side (Allpac 487)

The springs are stationery and outside the pumped medium, which makes the High-performance slurry seal for corrosive applications very suitable for slurry applications.

-

High-pressure slurry seals Features

- Springs outside the product avoid clogging

- Faces are made from silicon carbide

- Large clearances between seal and shaft sleeve

- Robust construction

- Metal-free design optional

- Single and dual seal designs available

- Cartridge and component designs available

- Single and multiple spring designs available

Available Configurations

Allpac 480 Balanced, multiple spring, single cartridge seal Allpac 481 Balanced, single spring, single cartridge seal Allpac 482 Balanced, Super X wave spring, single cartridge seal Allpac 483 Balanced, multiple spring, single component seal Allpac 486 Balanced, multiple spring, ID-pressurized, dual cartridge seal Allpac 427 Unbalanced, multiple spring, dual cartridge seal Allpac N-2000 DIN/ISO standard balanced, multiple spring, dual cartridge seal Allpac N DIN 24960 form C standard balanced, multiple spring, dual component seal; available in four sizes only. Operating Parameters

Pressures to 50 bar (725 psi) Temperatures from -40°C to 220°C (-40°F to 430°F) Speeds to 50 m/s (164 fps)

Industries that suit Slurry Seals Mechanical Seal

- General Industries

- Pulp & Paper

- Mining

- Steel and Primary Metals

- Food & Beverage

- Corn Wet Milling & Ethanol

- Other Industries

- Chemicals

- Basic (Organic & Inorganic)

- Specialty (Fine & Consumer)

- Biofuels

- Pharmaceutical

- Petrochemicals

- Water

- Water Management

- Wastewater

- Agriculture & Irrigation

- Flood Control System

- Oil & Gas

- Upstream Exploration & Production

- Downstream Processing

QBU Flowserve

QBU Flowserve

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve QBU is a single, balanced, multi-spring pusher seal engineered for boiler feedwater and circulation pumps where external cooling is not available. Its lube-groove seal face design enables heat dissipation through the process fluid, providing reliable performance in high-temperature hot water environments. Designed to comply with API 682, the QBU is ideal for utility, refining and petrochemical applications. It offers longer operational life and reduced maintenance compared to conventional seal types in thermal services. |

QBU Flowserve Key Features:

-

No external cooling required

-

Lube-groove face design dissipates heat efficiently

-

Engineered for boiler feed, circulation, and hot water pumps

-

Compatible with a wide range of API 682 applications

-

Multi-spring, balanced construction for long-term sealing integrity

Applications:

Cooling Systems, Boiler Feedwater Systems, Steam Systems, Heavy Oil and Upgrading, Water Injection, SAGD, Condensate Systems, Utilities, Petrochemical Refining

QB Seal Installation InstructionsLet us help you match the right Flowserve seal for your process, pump type and plant conditions. Contact our team now for technical consultation or a fast quotation.

Flowserve ISC1PX Cartridge Seal

Flowserve ISC1PX Cartridge Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve ISC1PX is a single pusher mechanical seal engineered for general-purpose industrial applications. It features a modular cartridge design with stationary springs located outside the pumped product, minimizing exposure to corrosive fluids. Developed for both ANSI and DIN standard chemical pumps, the ISC1PX offers interchangeable components within the ISC family, helping reduce maintenance time and costs. Its seal face geometry, available in carbon and silicon carbide, ensures consistent, stable sealing performance even under demanding process conditions. |

ISC1PX Cartridge Seal Key Features

-

Single pusher cartridge seal with external stationary springs

-

Modular design with compatibility across ISC seal versions

-

Optimized face geometry for long-term performance

-

Broad material options to suit chemical and slurry applications

-

Designed for standard and enlarged bore ANSI, and DIN chemical pumps

Applicable Standards

-

ASME (ANSI)

-

ISO

Common Applications

Need technical assistance or pricing? We help you select the right seal for your specific pump and process needs. Get in touch for technical support, custom quotes or more product information.

Flowserve RA / RA-C Outside Mounted Seal

Flowserve RA / RA-C Outside Mounted Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve ISC1PX is a single pusher mechanical seal engineered for general-purpose industrial applications. It features a modular cartridge design with stationary springs located outside the pumped product, minimizing exposure to corrosive fluids. Developed for both ANSI and DIN standard chemical pumps, the ISC1PX offers interchangeable components within the ISC family, helping reduce maintenance time and costs. Its seal face geometry, available in carbon and silicon carbide, ensures consistent, stable sealing performance even under demanding process conditions. |

RA / RA-C Outside Mounted Seal Key Features

-

Single, balanced, pusher-type mechanical seal

-

External mounting outside the seal chamber

-

No wetted metal parts in RA-C version

-

Ideal for corrosive chemicals and slurry processes

-

RA model includes two-piece rotary collar for robust fit

Applicable Standards

-

Suitable for ANSI and DIN standard pump installations

-

Designed to operate above 15 psi (1 bar), where RO seals are not recommended

Typical Applications

-

Acid transfer and slurry processing

-

Chemical manufacturing and wastewater treatment

-

Food and beverage systems

-

Polymers, coatings, and cryogenic services

-

Non-metallic pump systems

-

HVAC and water supply

Need help selecting the right seal? Our technical team is ready to support your system requirements. Contact us to discuss sizing, compatibility or to request a quotation.

Flowserve U Series Mechanical Seals

Flowserve U Series Mechanical Seals

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve U Series mechanical seals are engineered for high pressure corrosive and non-corrosive services, widely used in petrochemical and refinery environments. Designed in compliance with API 682 standards, this series offers versatile solutions for the most demanding applications. The UC model incorporates a canned seal face design with encapsulated graphite-gasketed silicon carbide rotating faces for excellent low-emission sealing. The UCQ variant is optimized for light hydrocarbons with low specific gravity, while the UOP option includes a 4-piece rotating face for extreme pressures up to 1500 psi. |

U Series Mechanical Seals Key Features:

-

API 682 compliant for high-integrity applications

-

Designed for specific gravity ? 0.45

-

Canned face design for low emissions

-

Enhanced reliability for long service life

-

Optional multi-port flush and custom configurations

-

Used in vertical and horizontal pump applications

Target Industries:

-

Distillation & delayed coking

-

Hydrocracking & hydrotreating

-

Boiler circulation & feedwater systems

-

Steam and condensate systems

-

SAGD and heavy oil upgrading

-

Crude oil transfer and pipelines

-

Catalytic cracking & alkylation units

-

Tank farms and utilities

U Series Installation Instruction

Need Help Choosing the Right Seal? Our team is ready to guide you through your seal selection process for heavy-duty and high-pressure operations. Contact us today for technical support, pricing and lead time.

Flowserve U Series High Pressure Mechanical Seals

Flowserve U Series High Pressure Mechanical Seals

| Brand | Flowserve |

|---|---|

| Description | Dual Pusher Cartridge Seal ISC2PP |

Seal Configurations:

-

UC – Standard model for general high-pressure sealing, includes encapsulated graphite-gasketed silicon carbide rotating face for superior sealing and emission control.

-

UCQ – Optimized for light hydrocarbon service with specific gravities down to 0.45. Multi-port flush support.

-

UOP – Engineered for extreme pressure with a four-piece rotating face and high-pressure stationary face. Handles pressure up to 1500 psi (103.4 bar).

U Series High Pressure Mechanical Seals Key Features:

-

API 682 compliant for high-integrity applications

-

Designed for specific gravity ? 0.45

-

Canned face design for low emissions

-

Enhanced reliability for long service life

-

Optional multi-port flush and custom configurations

-

Used in vertical and horizontal pump applications

Target Industries:

-

Distillation & delayed coking

-

Hydrocracking & hydrotreating

-

Boiler circulation & feedwater systems

-

Steam and condensate systems

-

SAGD and heavy oil upgrading

-

Crude oil transfer and pipelines

-

Catalytic cracking & alkylation units

-

Tank farms and utilities

Need Help Choosing the Right Seal? Our team is ready to guide you through your seal selection process for heavy-duty and high-pressure operations. Contact us today for technical support, pricing and lead time.