DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

Brand |

Description |

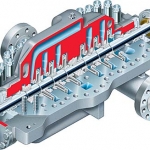

| Flowserve | The Flowserve DMX is an axially split, multistage pump designed to DMX ISO 13709/API 610 (BB3), latest edition. DMX pumps are particularly suited for high-pressure applications, delivering reliable performance and efficiency in demanding environments. |

DMX ISO (BB3) Between Bearings Pump Applications

The Flowserve DMX is an axially split, multistage pump designed to API 610 (BB3), latest edition. DMX pumps are particularly well suited for process charge, pipeline and injection services where uncompromising reliability over wide ranges is imperative.

- Applications:

Ground Water Development and Irrigation, Gas to Liquids, Hydraulic Press (metals), Hydrocracking, Hydrotreating, Boiler Feed, LNG, Boiler Feed (pulp and paper), Crude, Product and CO2 Pipeline, Nuclear Service, Desalination, Renewable Fuel Production, Descaling, Water Supply and Distribution (water), Dewatering and Water Supply (mining), Water Supply and Treatment (oil and gas), Distillation (oil and gas), Water and CO2 Injection, Drilling and Production, FPSO, Gas Treating and Sulfur Recovery, Heavy Oil, Oil Sands and Shale - Industries:

Oil and Gas, Power Generation, Primary Metals, Mining, Water Resources, Chemical Processing, Pulp and Paper

Pump Design incorporates double volute hydraulic passages for radial thrust balance and opposed impeller mounting for axial thrust balance.

Seal Chambers to API 682 dimensional criteria allow for installation of cartridge design single, dual unpressurized and dual pressurized mechanical seals to meet safety and environmental requirements.

Shaft Options include double extension for connection to auxiliary pumps or hydraulic turbines, and special shaft end machining for hydraulic fitted couplings.

Baseplates Designs and Pump Packages engineered to contract requirements.

Dynamic Balancing and TIR Verifications on assembled rotors assure optimum mechanical performance throughout the operating range.

Features:

- Choice of bearings

- Ball radial and thrust

- Sleeve radial and ball thrust

- Sleeve radial and tilting pad thrust

- Tilting pad radial and tilting pad thrust

- Choice of materials

- Carbon steel

- 12% chrome

- Austenitic and duplex stainless steels

- Monel

Operating parameters

- Flows to 2950 m3/h (13 000 gpm)

- Heads to 2130 m (7000 ft)

- Pressures to 275 bar (4000 psi)

- Temperatures to 200°C (400°F)

- Speeds to 6000 rpm