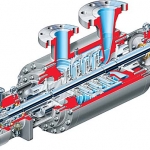

WXB Between Bearings, Diffuser Casing, Multistage, Process Barrel Pump

The Flowserve WXB is a between bearings multistage process barrel pump featuring a diffuser casing, engineered for high-pressure high-temperature services in hydrocarbon processing, water injection, and power generation. Designed according to API 610 (BB5) standards, the WXB delivers exceptional reliability, thermal stability and serviceability in critical process environments. The WXB is a multistage, diffuser-casing barrel pump with tandem impellers and a balance drum to carry axial thrust forces. It is designed for users who need the hydraulic range and performance of a ring section pump, but demand the design and maintenance attributes of a barrel pump. FPSO, Dewatering and Water Supply (mining), Heavy Oil, Oil Sands and Shale, Hydrocracking, Hydrotreating, LNG, Primary Processing (mining), Residuum and Heavy Oil Upgrading, Water and CO2 Injection, Auxiliary (chemical), Boiler Feed, Boiler Feed (pulp and paper), Descaling, Catalytic Cracking, Crude, Product and CO2 Pipeline, Gas to Liquids Radially Split, Multivane Diffuser Construction results in balanced radial loads over the entire flow range, including partial-load operation. Cartridge-Style Inner Case Sub-Assembly includes the rotor, discharge head, suction head and bearing assembly. This cartridge-style construction allows the entire assembly to be removed as a single unit to facilitate maintenance. Axial Thrust Balancing Device creates nearly constant axial thrust throughout the pump’s operating range for improved efficiency. Precision Cast Impellers are dynamically balanced to ensure hydraulic efficiency and performance repeatability. Large-eye first stage impeller optimizes NPSH characteristics. Radial Bearings are sleeve mounted anti-friction deep groove and thrust bearings are sleeve mounted back-to-back angular contact type. The bearing lubrication system includes an oil bath, a constant level oiler and an oil sight glass. WXB centrifugal pumps User Instructions Operating under extreme pressure and temperature? The WXB barrel pump delivers proven performance where it matters most. Contact us to configure a WXB unit that matches your system’s toughest requirement WXB Between Bearings, Diffuser Casing, Multistage, Process Barrel Pump

WXB Between Bearings, Diffuser Casing, Multistage, Process Barrel Pump

Brand:

Worthington

Description:

WXB Between Bearing Pump Applications:

Power Generation, Primary Metals, Oil and Gas, Pulp and Paper, Chemical Processing, MiningOperating Parameters