WTB Between Bearings, Two- and Three-Stage, Radially Split Process Pump

WTB Between Bearings, Two- and Three-Stage, Radially Split Process Pump

WTB Between Bearings, Two- and Three-Stage, Radially Split Process Pump

| Brand: | Worthington |

|---|---|

| Description: |

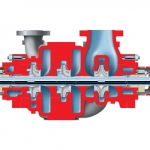

The Flowserve WTB is a radially split between bearings pump available in two- and three-stage configurations, designed for high-pressure chemical and industrial process services. With a compact layout and excellent shaft stability, the WTB is ideal for boiler feed, pipeline boosting, and refinery circulation systems that demand consistent performance and low vibration. |

The WTB pump is a between bearings, radially split, volute type process pump engineered to provide safe, reliable operation at elevated temperatures and pressures. The two-stage WTB is fully compliant with ISO 13709/API 610 (BB2). The three-stage WTB meets all the key ISO13709/API 610 (BB2) requirements.

WTB Between Bearings Process Pump Applications

Acid Transfer, Hydrotreating, Boiler Feed, LNG, Catalytic Cracking, Caustic and Chlor-alkali, Offsites and Waste Treatment, Residuum and Heavy Oil Upgrading, Distillation (oil and gas), Solvents, Volatile Organic Compounds, FPSO, Water and CO2 Injection, Gas to Liquids, Geothermal Well Services, HVAC, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Hydrocracking, Industrial Gases

- Industries:

Chemical Processing, Power Generation, Oil and Gas, General Industries - Standards:

API682, API610

Heavy-Duty, Dual Volute Casing With an Integral Crossover ensures radial hydraulic balance and stable performance over the pump’s full operating range. Shaft deflection and vibration are virtually eliminated.

Centerline Supported, Radially Split Design prevents distortion at high temperatures and pressures. Fully confined gasket fits provide superior sealing versus horizontally split case pumps.

Dynamically Balanced Impellers ensure hydraulic efficiency and are positively locked to the shaft to eliminate vibration.

Double-Suction First-stage Impeller minimizes axial thrust and significantly reduces NPSHR, often eliminating the need for booster units.

Rotor Hydraulic Balance is achieved by using an inherently hydraulically balanced double-suction impeller in tandem with second- and third-stage impellers with balance holes.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations.

Operating Parameters

- Flows to 1400 m3/h (6165 gpm)

- Heads to 1100 m (3610 ft)

- Pressures to 108 bar (1565 psi)

- Temperatures to 430°C (800°F)

- Speeds to 3600 rpm

Looking to boost system pressure without compromising stability? The WTB pump is built for multi-stage process reliability. Send us your duty specs and we’ll help identify the best stage and material combination