WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

| Brand: | IDP |

|---|---|

| Description: |

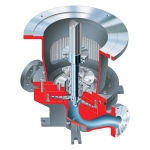

The Flowserve WMA is a rigidly coupled vertical in-line pump built to ISO 13709 / API 610 (OH4) standards. It shares the same proven hydraulics as the WMA2 and HWMA2 models, offering reliable performance in low-flow, high-head conditions. Compact and efficient, the WMA pump is ideal for tight-space installations in refineries, chemical plants and general industrial services. Itsju78/ OH4 construction ensures shaft stiffness, alignment integrity and minimal vibration for long-term operation with reduced maintenance. |

The WMA is a rigidly coupled, ISO 13709/API 610 OH4 design vertical in-line pump and features the same hydraulics as the HWMA. The WMA uses a P-base motor and is shorter in height than the ISO 13709/API 610 OH3 design of the HWMA.

Flowserve WMA Applications

Catalytic Cracking, Hydrotreating, Caustic and Chlor-alkali, LNG, Chemical and Liquor (pulp and paper), Leaching Acid, Cooling Water (power), Crude, Product and CO2 Pipeline, Plating, Galvanizing and Other Coatings, Residuum and Heavy Oil Upgrading, Digester, Solvents, Volatile Organic Compounds, Distillation (oil and gas), Drilling and Production, Water Supply and Treatment (oil and gas), FPSO, Water and CO2 Injection, Gas Treating and Sulfur Recovery, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Acid Transfer, Hydrocracking, Boiler Feed Booster, Industrial Gases

- Industries:

Chemical Processing, Power Generation, Oil and Gas, General Industries - Standards:

API610, API682

Replaceable Volute Insert permits precise hydraulic customization. Each insert is engineered for specified head and flow requirements. Accommodates future system changes.

Rigid Coupling ensures precision shaft alignment while eliminating time-consuming manual alignment.

Casing and Cover feature metal-to-metal fits with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Raised Face Flanges are to ASME B16.5, Class 300 for one stage and Class 600 for two-stage models.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Stiff Shaft Design limits deflection at seal faces to 0.05 mm (0.002 in) max. Vibration levels are well below that required by ISO 13709/API 610.

Operating Parameters

- Flows to 45 m3/h (200 gpm)

- Heads to 220 m (725 ft)

- Pressures to 50 bar (750 psi)

- Temperatures to 260°C (525°F)

Need a space-saving vertical pump that doesn’t compromise on pressure performance? The WMA pump delivers OH4 strength in a compact form. Let us help you size and specify the best WMA configuration for your application.