VPL3200 Engineered Vertical Cantilever Pump

VPL3200 Engineered Vertical Cantilever Pump

VPL3200 Engineered Vertical Cantilever Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: |

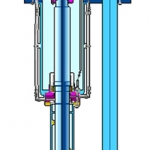

The Lawrence Pumps VPL3200 is a heavy-duty vertical cantilever pump engineered for aggressive chemical and slurry applications. With a true cantilever shaft and no submerged bearings, bushings or seals, it is ideal for open sump or sealed tank installations where flushing is not possible or desirable. The pump offers consistent performance in services such as scale recycle, waste treatment and slurry handling across chemical, mining, and power industries. |

The VPL3200 is a true cantilever pump, without any submerged bearings, bushings or rings. The highly versatile VPL3200 is available for sump and sealed tank-mounted applications. It is particularly well-suited for applications where flushing liquids are not available or cannot be tolerated.

VPL 3200 Applications

Scale Recycle, Slurry Processing, Offsites and Waste Treatment, Auxiliary Services (power), Descaling, Slurry Transfer (mining)

- Industries:

Chemical Processing, Mining, Primary Metals, Power Generation, Oil and Gas

Numerous Casing and Impeller Hydraulics are available to precisely fit performance requirements. Configurations include bottom suction, top suction, double-suction, double volute, slurry and non-clogging designs.

The Impeller is keyed to the pump shaft and secured using an impeller nut. Clearances are easily adjustable at the thrust bearing location.

The Shaft prevents is designed to operate approximately 30% below the first critical speed. The pump can operate over the complete capacity-head range without restriction.

Heavy-duty, Anti-friction Thrust and Radial Bearings are located above liquid level and accommodate all axial and radial loads without transmitting any loads to the driver.

Grease Lubrication is standard, although oil mist, forced oil, or internally circulated self-contained oil lube systems are available.

Dry-run capability with no adverse affects.

Many Options are available to suit site requirements. These include:

- Inducer

- Suction tailpipe

- Mechanical or hydraulic agitation

- Basket-type screen

- Abrasion- or corrosion-resistant materials of construction

- Several driver types

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 4542 m3/h (20 000 gpm)

- Heads to 91 m (300 ft)

- Temperatures to 593°C (1100°F)