Unique Tank Outlet MixProof Valve

Unique Tank Outlet MixProof Valve

Processed Foods, Dairy, Beverages, Home & Personal Care

Cost effective tank outlet mixproof valve

Alfa Laval Unique Mixproof TO valves feature two independent plugs. It is the choice for hygienic installations enabling safe filling or emptying of tanks.

Exceptional spillage-free operation

A state-of-the-art double-seat design provides long-lasting, spillage-free operation thus minimizing the risk of product contamination. The use of double lip seals provides added protection to ensure safe and hygienic operation.

Easy valve to maintain and clean

Unique mixproof valves feature a top-loaded design, making maintenance fast and easy. It also features no adjustable components, a maintenance-friendly actuator and built-in leakage detection on all seals. Unique mixproof valves meet most hygienic standards and can be supplied with the optional SpiralClean cleaning system.

Valve clusters – customized flow solutions

We are specialists in providing pre-built valve clusters customized to meet specific, individual requirements. Our expertise helps ensure you the most efficient flow management, using as few components as possible and dealing effectively with key issues that include thermal cycling, cleanability, drainability and flow control. Alfa Laval valve clusters can be supplied pre-assembled and pre-tested as well as fully wired and with all the necessary pneumatic tubing, junction boxes and control panels pre-connected. This means you can bring even complex installations online as quickly as possible, saving time and avoiding lost revenue associated with on-site troubleshooting and downtime.

For more information, please refer to Documentation and to the Selection Guide.

For cost-effective alternatives to the Unique mixproof valve range, Alfa Laval also offers standard SMP mixproof valves.

The unique mixproof valve concept is based on a series of base components, including valve body, valve plug, actuator and cleaning options and accessories that support a wide range of applications. Using these components, you can build a Unique mixproof valve to match your exact process requirements.To facilitate maintenance, the Unique mixproof valve also features leakage detection holes that provide advance notification of wear or damage to static o-rings. Operators can visually inspect the valve at any time without having to disassemble it.

Operating principle

The Alfa Laval Unique mixproof valve is a normally closed (NC) valve that is controlled from a remote location by means of compressed air.

To separate the two liquids, the valve has two independent plug seals. The space between the two seals forms an atmospheric leakage chamber. In the rare case of accidental product leakage, the product flows into the leakage chamber and is discharged through the leakage outlet.

When the valve is open, the leakage chamber is closed. The product can then flow from one line to the other without spillage. The valve can easily be cleaned and protected against the effects of water hammer according to the specific requirements of the process and the configuration of the valve. (There is no product spillage during valve operation).

SpiralClean System

To ensure the hygienic operating condition of its Unique mixproof valve range, Alfa Laval offers its SpiralClean system to clean the upper and lower balanced plugs and leakage chamber of the valves. Using less cleaning fluid, utilities and time, SpiralClean cleans more thoroughly and efficiently than conventional cleaning devices. All external CIP systems for Unique mixproof valves include the SpiralClean design as standard.

Another big benefit: SpiralClean enables the Unique mixproof valve to operate under aseptic-like conditions, creating a steam barrier to the atmosphere upon applying steam to the CIP pipes.

Options

- 3-A version available upon request

- Product wetted seals HNBR, NBR or FPM

- Male parts or clamp liners in accordance with required standard

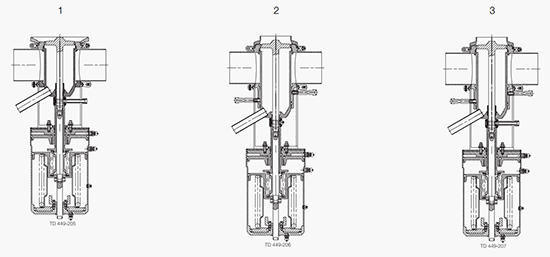

- Control and indication: ThinkTop or ThinkTop Basic

- Side indication for detection of upper seat lift

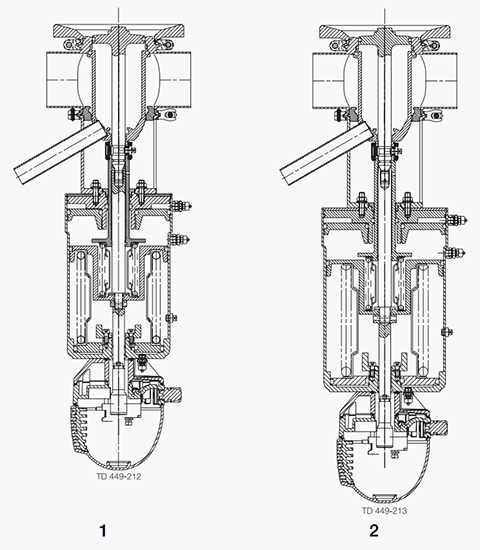

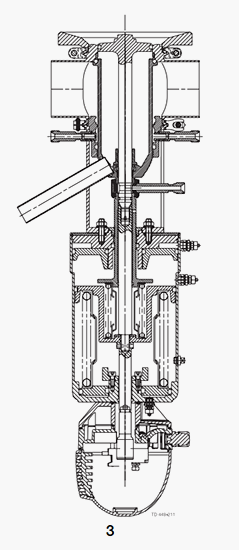

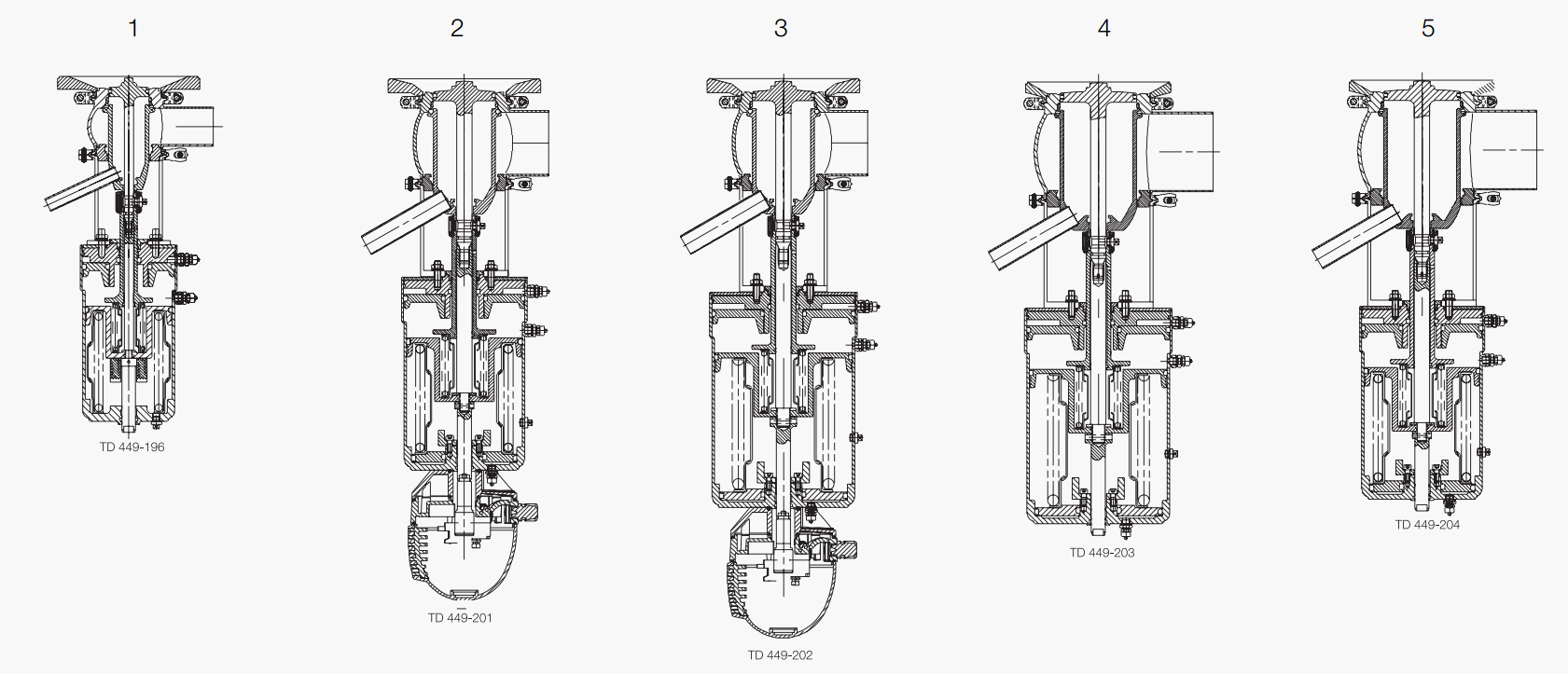

Unmatched flexibility is the concept of this simple mixproof valve. Its modular design provides the perfect solution for all mixproof tank outlet applications involving non-compatible fluids within the pipeline and tank. The body and outlet can be easily positioned by loosening a single clamp. The body is connected to a flange that is welded directly to the tank.The tank flange maintains TÜV approval AD 2000 and comes with an EN10204 (3.1) inspection certificate 3.1. The Unique TO is available in two inch to four inch outlet (ISO tube) sizes. The design of the valve allows it to be installed in a horizontal configuration.

The Unique TO is remotely controlled by means of compressed air. The valve is supplied in a normally-closed (NC) configuration. The valve maintains two independent plug seals, forming a leakage chamber which is open to the atmosphere at all times. In the unlikely event of a leak, product will enter into the leakage chamber and be discharged through a leakage chamber outlet. As the valve opens, the leakage chamber closes allowing product to flow from the tank to the pipeline. The valve is protected from any pipeline water hammer thanks to a balanced plug design that limits the speed of the seating of valve plug when closing with the direction of the product flow. The valve has multiple cleaning options, configurable to the needs of the specific application. There is practically no spillage of product when operating the valve.

Unique Tank Outlet MixProof Valve Application

Unique TO meets the typical demands of a process valve in the sanitary industry. It is also suitable for products with solids. Cleaning of the plugs and seats are performed by means of seat lift during normal cleaning procedure. This valve also includes a balanced plug in the pipeline that protects against pressure shock in the pipeline when closing in the direction of product flow. Features include an actuator with balanced seat lift integrated and standard balanced plug in pipeline. Unique TO is the choice for standard solutions.

- Unique TO

- Unique TO long stroke (size 2.5 inch to 3 inch ISO63.5-ISO76.1 and DN65-DN80)

- Unique TO with external cleaning

Unique TO with external cleaning meets the highest demands for hygienic processing. During the cleaning process, the plugs can be lifted independently to ensure cleaning of plugs and seats together with their corresponding pipe. At the same time or separately the leakage chamber and balanced plugs can be cleaned with our SpiralClean system. It has few product wetted seals and allows no product spillage during operation. This valve is the choice for solutions requiring the highest level of hygiene and is suitable for applications with sticky products, products with high content of solids or applications where “close to aseptic conditions” are wanted. Its features include an actuator with seat lift integrated and SpiralClean of leakage chamber and balanced plug. Unique TO with external cleaning is the choice for highest hygienic cleaning.

Materials

| Product Wetted Steel Parts | 316L |

| Other Steel Parts | 304 |

| Product Wetted Seals | EPDM, HNBR, NBR, or FPM |

| Other Seals | CIP seals: EPDM Actuator seals: NBR |

| Finish Options | Internal/external matte (blasted) Ra<64µ” Internal bright (polished) Ra<32µ” Internal/external bright (internal polished) Ra<32µ” |

Note: The Ra values are only for the internal surface.

Technical Data

| Product Pressure in Pipeline (max) | 10 bar / 145 psi (1000 kPa) (For higher pressure, call Central States Industrial (CSI) at 800.654.5635) |

| Product Pressure (min) | Full vacuum |

| Temperature Range | 23°F – +257°F (depending on seal material) (For higher temperature, call Central States Industrial (CSI) at 800.654.5635) |

| Air Pressure | Max. 8 bar / 116 psi (800 kPa) |

SpiralClean

The Unique TO offers the Alfa Laval SpiralClean system to clean the balanced plug and leakage chamber, helping to meet the high hygienic standards of the sanitary industry. All external clean-in-place (CIP) systems for Unique include the SpiralClean design as standard. Another benefit of the SpiralClean system is that it allows the Unique TO to operate under near-aseptic conditions by applying steam to the CIP pipes, thereby forming a steam barrier to the atmosphere.

Options

The Unique TO is designed with user flexibility in mind. The user can choose additional options as warranted by the application (i.e., stricter hygienic requirements, challenging downstream flow characteristics). The modular design of Unique TO uses common components from the Unique valve family, reducing the requirement for spare parts inventory while providing an extremely serviceable valve. The valve design consists of a single valve body, connected to either a tank flange or a stub flange via a clamp.

UNIQUE TO SIZE FLEXIBILITY

- 2″ – ISO51 and DN50 with size 3-Basic actuator

- 2½”-3″ – ISO63.5-ISO76.1 and DN65-DN80 with size 4-Basic actuator

- 2½”-3″ – ISO63.5-ISO76.1 and DN65-DN80 with size 5-Basic actuator

- 4″ – ISO101.6, DN100, DN125 and DN150 with size 5-Basic actuator

- 4″ – ISO101.6, DN100, DN125 and DN150 with size 4-Basic actuator (e.g. tank filling valve)

UNIQUE TO HYGIENIC FLEXIBILITY

- CIP in leakage chamber by use of spiral clean

- With external CIP cleaning in sealing element by use of spiral clean

- With external CIP cleaning in sealing element and CIP in leakage chamber by use of spiral clean

Other Options

For control and indication of both upper and lower seat lift as well as main movement, please call Central States Industrial (CSI) at 800.654.5635.

3-A Sanitary Standard labeling is available on request.

Need a safe and efficient way to drain your hygienic tanks? Get in touch today to explore how the Alfa Laval Unique Tank Outlet Mixproof Valve improves product safety and cleanability.