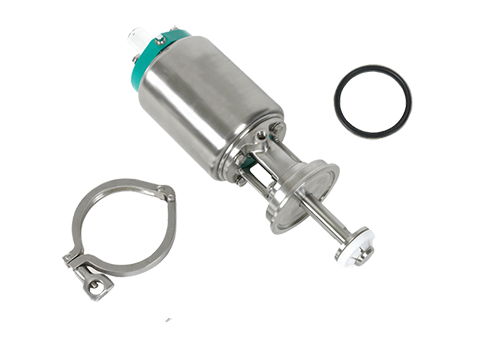

Tri-Clover 736 Swap Valve

TRI-CLOVER 736 SWAP VALVE

Do you have Tri-Clover® 361 valves in your facility? If you’re ready for newer technology but not able to make the change to a new valve body, ABS offers the Tri-Clover 736 “swap” valve from Alfa Laval as a solution.

The 736 valve is designed to bridge the gap when an older 361 valve fails, but a complete valve upgrade isn’t feasible. Since the swap valve consists of a complete 761-style valve, installation is quick and easy with no cutting or welding required.

The 736 valve provides the same reliable, sanitary, and flexible design expected from Alfa Laval’s 700 series valves. A variety of options allows customization to your system’s needs. Even without a complete overhaul, you can still expect years of reliable performance.

Related Industries: Processed Foods, Dairy, Beverages, Brewery, Home & Personal Care, Chemical

Tri-Clover 736 Swap Valve Application

The 736 valve converts existing welded-in Tri-Clover 361 series shut-off valves into a Tri-Clover 700 series equivalent, delivering all the benefits without cutting or welding.

Working Principle

The valve is remote-controlled via compressed air. It has few moving parts, resulting in high reliability.

Standard Design

The 736 valve features a specially designed bonnet that allows easy replacement of 300 series shut-off valves:

- Remove the body-bonnet clamp

- Remove 300 series components (stem to actuator)

- Install the 736 swap valve and gasket

- Reattach with the provided clamp

The 736 valve supports all 761 valve spares and features, including ThinkTop and GreenTop indication units, TR2 and LP elastomer stems, high-pressure, and sealed-for-life reversible actuators.

Actuator Functions:

- Pneumatic downward movement, spring return (NO)

- Pneumatic upward movement, spring return (NC)

- Pneumatic upward and downward movement (A/A)

- Optional actuator for intermediate valve plug position

Materials:

| Product Wetted Steel Parts | 316L |

| Other Steel Parts | 304 |

| Plug Stem | Buna bonded or TR/TR2 PTFE replaceable (standard), EPDM or SFY (optional) |

| Product Wetted Seals | Buna (standard), EPDM or SFY (optional) |

Technical Data:

| Max Product Pressure | Depends on valve specification and size (contact CSI) |

| Max Temperature | 200 – 284°F (EPDM) |

| Air Pressure | 60 – 80 psi |

Dimensional Data:

| Valve Size (Tube OD) (in) | A – Short (in) | A – Long (in) | C (in) |

|---|---|---|---|

| 2.0 | 17.32 | 21.25 | 3.50 |

| 2.5 | 17.56 | 21.53 | 3.50 |

| 3.0 | 18.06 | 22.03 | 3.75 |

Options:

- Control and indication (Control Top or ThinkTop®)

- High pressure actuator for 2.5 and 3.0 inch sizes

- Three-position actuator

- Long-stroke actuator

Pressure Drop/Capacity Diagram

Shut-off valve flow pattern: B to A (solid curve), A to B (dashed curve)

Note: Diagram based on water at 68°F, measured per VDI 2173 standards.

Looking to minimise product loss and ensure safe flow transitions?

Explore the Alfa Laval Tri-Clover 736 Swap Valve with us today.