T ECO MAG-M

T ECO MAG-M

T ECO MAG-M

T ECO MAG-M Operating Limit

- Max viscosity: 200 cSt

- Max system pressure: 16 bar

- Flow: up to 1.5 m³/h

- Head: up to 85 m

- Temperature range: from -185 °F (?120 °C) to +662 °F (+350 °C)

- Electric motors: from 0.55 to 2.2 kW

- Available ATEX II – / 2G cbk II C T2-T5

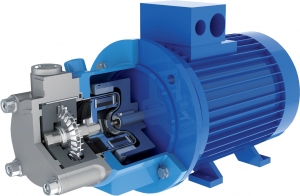

Horizontal, sealless peripheral pump with permanent magnet drive system (no mechanical seal). Designed for low flow and high head applications. Smart construction ensures quick maintenance and great value for money.

The rear shell is a single-piece, no-weld design made of AISI 316, with a pressure rating of up to 16 bar. Special profile designed to withstand higher pressure than traditional models.

The hydraulic system includes a self-balancing impeller to extend wear ring life. Product-lubricated bearing system is field-assembled and requires no special tools.

Volute/Bearing materials:

- Carbon graphite volute + stainless steel shaft

- Antimony carbon volute + Silicon Carbide shaft

CF8M pump casing and impeller are precision CNC machined from high-quality castings for optimal performance.

RWP Quick Change Cartridge Kit

Allows for fast and easy maintenance.

O-ring gasket sealing system with multiple material options:

- VITON® (standard)

- GRAPHOIL

- ARAMIDIC

- FEP

Painted with epoxy primer and polyacrylic enamel (water-based) for strong resistance and environmental compliance.

Features high-power synchronous magnetic coupling designed by in-house technical team using rare earth magnets (mechanically locked). High temperature version available up to +662°F (+350°C).

Quick T ECO MAG-M Maintenance (3 steps):

- Unscrew pump cover

- Extract the cartridge using one of the cover screws

- Insert new cartridge and reassemble pump

Looking to reduce energy costs without compromising reliability? Discover how T ECO MAG-M supports sustainable process performance.