Scandi Brew (SB) Membrane Sample Valve

Scandi Brew (SB) Membrane Sample Valve

Scandi Brew (SB) Membrane Sample Valve

The Alfa Laval Scandi Brew Membrane Sample Valve provides a compact and cost-effective way to obtain bulk or aseptic samples of brewery, food, dairy and beverage products, including highly viscous products, such as harvest yeast.

Related Industries:

Food Processing, Dairy Processing, Beverage Processing

High sampling reliability

The valve meets the requirements for high-quality product extraction in various hygienic processes with minimal risk of contamination. High accuracy, exceptional repeatability and excellent reliability are hallmarks of the valve.

Versatile hygienic design

Made of a single piece of stainless steel, valve body features smooth, crevice-free surfaces. Because no welding is required, the risk of pore formation and cracking in the welds and subsequent risk of bacterial build-up is eliminated. This highly versatile hygienic valve is available in several different designs to ensure sample reliability and safety for a broad range of applications.

Enhanced valve cleanability

Designed to help ensure effective sterilization before and after each sample, these valves are sterilized in place with alcohol or steam. This helps ensure a truly representative sample every time.

Product Benefits

- Low upfront investment costs

- Superior hygiene

- Compact size

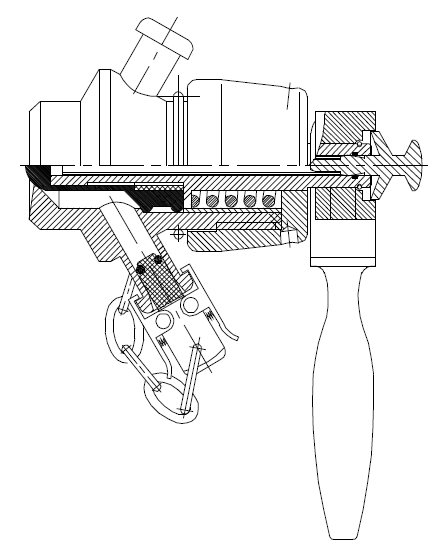

Construction

The valve consists of a valve body, actuator and membrane seal, which is placed on the stem of the actuator and works as a stretchable plug. The valve is available in three different actuator designs:

- Manual – For manual activation

- Manual + Micro Port – For manual activation or sampling using a hypodermic needle to penetrate the membrane for sample taking.

- Manual + Pneumatic – For manual or pneumatic activation when the valve is connected to pipes for automatic sampling. The valve is then supplied with pipe outlet connections.

Operating principle

To take a sample, rotate the handle in a clockwise direction to open the valve. This retracts the membrane allowing the liquid to pass through the valve into the sample container. To close the valve for sterilization before and after taking each sample, rotate the handle in a counter-clockwise direction to channel between the valve ports is open for sterilization.

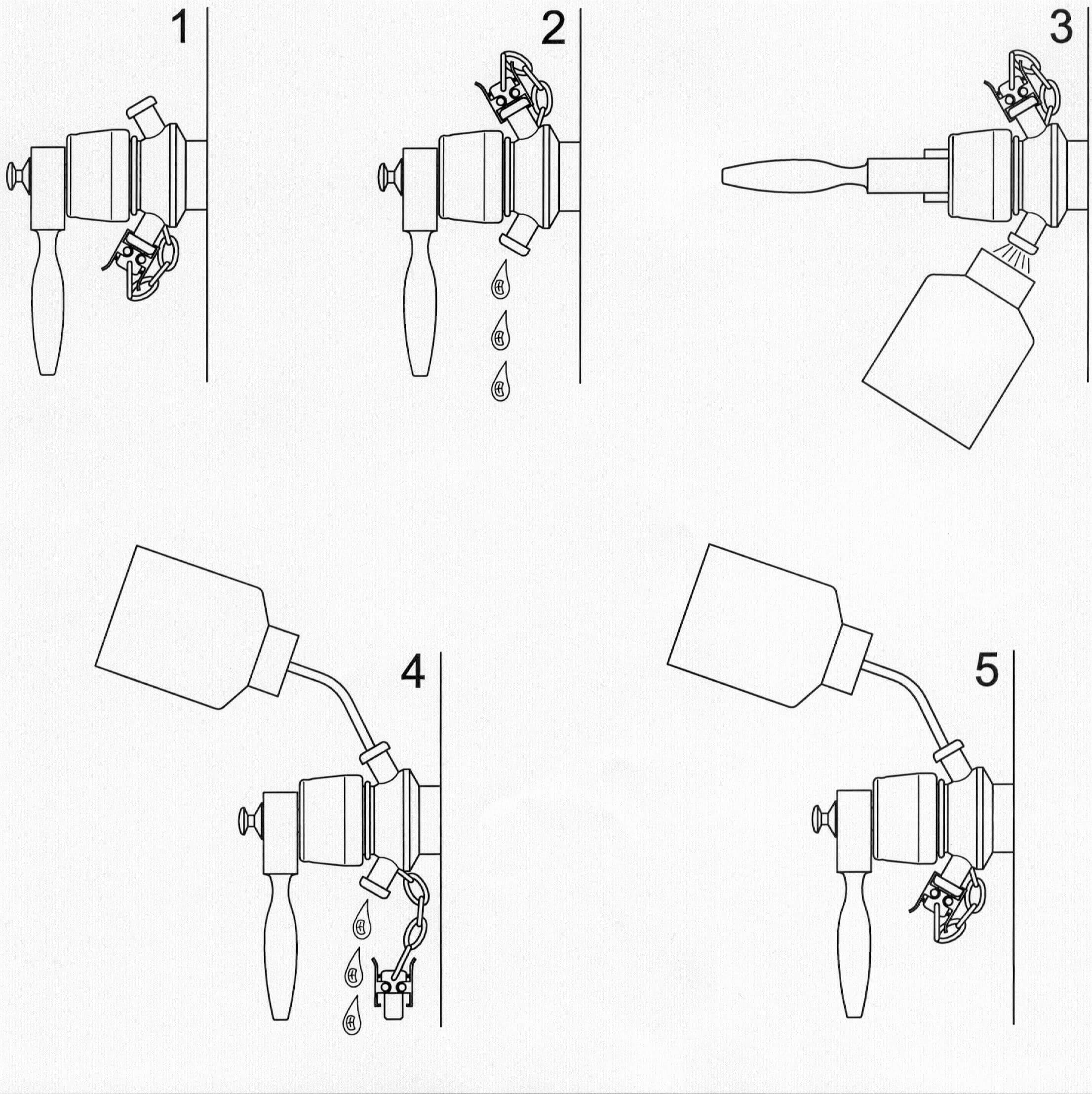

Function and cleaning

1 Alcohol sealed valve

2 Alcohol is drained and the valve can be steam sterilized

3 Sample is taken

4 Valve is flushed with water/alcohol

5 Valve is sealed with alcohol

Type W – Harvest Yeast Sample Valve

The valve is available in three different mounting designs:

Concept

The membrane sample valve is used for sampling from tanks and pipework under sterile conditions. The valve is sterilized in place with alcohol or steam. Membrane sealing directly against product ensures representative sampling, giving repeatable results safe to secondary contamination.

Working principle

Before opening the valve, the closing cap should be placed on upper hose piece. When handle is placed into horizontal position the required flow through the lower outlet is obtained. When handle is back into vertical position the valve is closed and the handle can be removed if required. Aseptic sampling is possible from a special valve type with micro port. By removing the red closing cap, a hypodermic needle can be inserted through a central channel into the membrane and the aseptic sampling takes place with the valve in closed position. After sampling the valve should be flushed with water or alcohol. Sterilization has to take place by means of alcohol or steam.

Standard Design

All types are available for manual or pneumatic operation. The two outlets are hose pieces designed as clip-on. The standard valve is equipped with one clip-on closing cap.

TECHNICAL DATA

Product pressure: . . . . . . . . . Max. 6 bar as standard.

10 bar is available on request

PHYSICAL DATA

Pressure

Valve body: . . . . . . . . . . . . .1.4404 (AISI 316L)

Other metallic parts: . . . . . . .1.4307 (AISI 304L)

Membrane: . . . . . . . . . . . . .Silicone. EPDM on request

Options

- Handle for operating the valve

- Assembling tool

- Membrane remover

- Proximity switch for indication of open/closed valve position

- Sampling coil with clip-on

- Isobaric hand bottling device with clip-on

- Hypodermic needle

- Silicone hose with clip-on

Alfa Laval SB Membrane Sample Valve – Product Leaflet – ESE01593

Instruction Manual – SB Membrane Sample Valve – ESE02963EN

Ensure safe and sterile product sampling with the Alfa Laval SB Membrane Sample Valve. Contact us today to learn how it fits your process.