M Hard Metal, Overhung Abrasive Slurry Pump

M Hard Metal, Overhung Abrasive Slurry Pump

M Hard Metal, Overhung Abrasive Slurry Pump

| Brand: | Worthington |

|---|---|

| Description: |

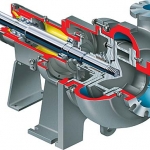

The Flowserve M Hard Metal, Overhung Abrasive Slurry Pump is specifically engineered for the harshest slurry applications. Designed to handle abrasive and corrosive slurries with high solids content, it is the pump of choice for mining, ore processing, and sand slurries. Built with rugged hard metal components and replaceable wear parts, the M pump delivers a longer service life, reduced maintenance and high reliability even in the most demanding conditions. |

The Flowserve type M hard metal slurry pump is a horizontal, single stage, end suction design with a tangential discharge nozzle. Fitted with a hard metal liquid end, the M pump is engineered to handle high concentrations of coarse, abrasive solids in suspension.

M Hard Metal, Overhung Abrasive Slurry Pump Applications

OEM, Primary Processing (mining), Scale Recycle, Slurry Processing, Slurry Transfer (mining), Leaching Acid, Coatings (pulp and paper), Dewatering and Water Supply (mining), Flue Gas Desulfurization, Heavy Oil, Oil Sands and Shale, Waste Processing

- Industries:

Chemical Processing, General Industries, Mining, Pulp and Paper, Power Generation, Primary Metals, Oil and Gas

Key Features

-

Hard metal construction for superior abrasion resistance

-

Closed impeller with external vanes reduces stuffing box pressure and prevents solids build-up

-

Heavy-duty bearing frame designed for belt loads and long operating life

-

Replaceable hook sleeve and impeller spacer with gasket seals for easier maintenance

-

Cavity-free casing design minimizes wear and ensures consistent flow

Operating Parameters

- Flows to 10 000 m3/h (44 000 gpm)

- Heads to 90 m (300 ft)

- Pressures to 10 bar (150 psi)

- Temperatures to 120°C (250°F)

- Solids from 2% to 70% by weight

Why Choose Flowserve M Hard Metal Slurry Pumps

-

Proven reliability in abrasive and corrosive slurry environments

-

Extended service life due to replaceable wear components

-

Lower maintenance frequency reduces downtime and costs

-

Engineered for heavy-duty performance in mining, oil sands and processing plants

FAQs

Q: What is an abrasive slurry pump?

An abrasive slurry pump is designed to handle slurries with high concentrations of coarse solids, such as those found in mining and mineral processing.

Q: What makes the Flowserve M pump unique?

Unlike standard pumps, the Flowserve M features rugged metallurgy, replaceable wear parts, and a closed impeller design that reduces recirculation and wear.

Q: Can the M slurry pump handle acidic or corrosive liquids?

Yes. Its hard metal liquid end and optional material selections make it suitable for acid leaching and abrasive chemical processes.

MJ Slurry Pump User Instructions

Need a pump that can take a beating from tough slurries? The M pump is made to handle it day in day out. Contact us now to talk through your abrasion challenges and material selection