Enhance your industrial operations with the robust and reliable Flowserve HED/HED-DS Between Bearings Pumps. Contact us today for expert guidance and solutions tailored to your needs.

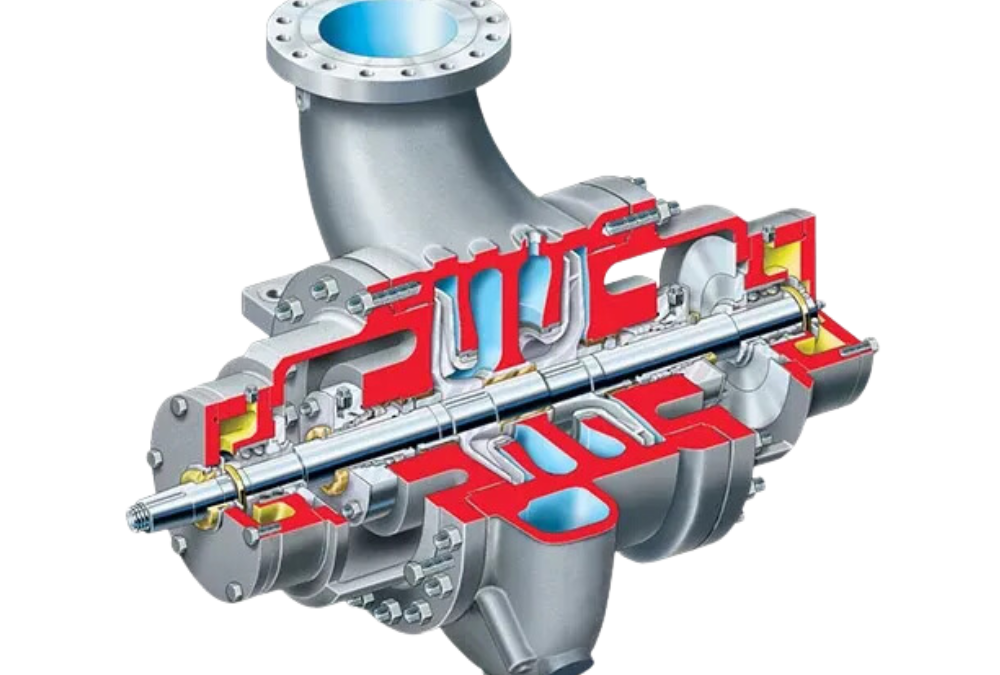

Flowserve HED/HED-DS Between Bearings Pumps – Radially Split, Single Case

Flowserve HED/HED-DS Between Bearings Pumps – Radially Split, Single Case

Flowserve HED/HED-DS Between Bearings Pumps – Radially Split, Single Case

The Flowserve HED and HED-DS are designed to deliver stable operation and high efficiency in the most demanding environments. With a radially split single case construction, these BB2-type pumps are trusted across the power generation oil and gas and industrial utility sectors where pressure extremes and tight operating margins are common.

The HED-DS features a double suction first-stage impeller that improves suction conditions without compromising hydraulic performance. Both models offer API 610 compliance centerline mounting and rugged shaft design that make them a dependable choice for critical systems like boiler feed water injection and amine circulation.

Satisfying the Needs of the Market

HED/HED-DS Between Bearings Pumps meet the standards set out by ISO 13709 and API 610 (BB2). In terms of design, the pumps are suitable for use in the hydrocarbon processing and power generation sectors. The following requirements are part of the specifications: bearing alternatives, material choices, centerline-mounted casing, mechanical seal chambers, nozzle loads and shaft run-out requirements under ISO 13709/API 610, and ISO 21049/API 682.

Double casing covers can be used to make maintenance easier.

When working with hot liquids, it is critical to use gasketing, which is a metal-to-metal fit that is completely confined and compressed under control, to ensure proper sealing and alignment.

For the most difficult applications, the ISO 21049/API 682 Seal Chamber can handle both pressurized and unpressurized cartridge seals. You have access to a complete set of seal flush plans that meet ISO 13709 and API 610 requirements. A pressure equalizing line is connected to the chamber on the discharge side to maintain consistent pressures in the seal chambers.

Class 600 Raised Face Flanges are ASME B16.5 compliant. The surface is smooth and meets the ISO 13709 and API 610 standards. Flanges of class 300 and 900 can be ordered if required.

Threaded dowels or locking pins are used to secure the wear rings on the impeller and regenerative casing. Wear rings are an inexpensive technique to improve the pump’s function and keep it running smoothly. Optional non-metallic wear rings come in a variety of exotic materials, including PEEK.

By carefully fitting the seal face, you can ensure easy maintenance and a long seal life.

Specifications

ISO 13709 / API 610 BB2

- Flows to 2000 m3/h (8800 gpm)

- Heads to 650 m (2100 ft)

- Pressures to 120 bar (1750 psi)

- Temperatures to 450°C (842°F)

Size Range: 2″ to 12″

Radially Split Single Case Pumps for Oil & Gas Applications

- Petroleum refining, production and distribution

- Heavy-duty chemical and petrochemical processing

- Liquefied gas industry service

- Boiler feed

- Heavy-duty utility service

Complementary Pump Designs

Type HED and HED-DS pumps may be used with many other Flowserve pump designs, including:

- Radially split, overhung process pumps

- Single-stage, between bearings pumps

- Multistage, between bearings pumps

- Vertical, double-case pumps