Flowserve DVSH Between Bearings Pump

Flowserve DVSH Between Bearings Pump

Flowserve DVSH Between Bearings Pump

Brand |

Description |

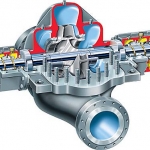

| Flowserve | Designed for continuous operation in heavy duty pipeline services, the DVSH is a between bearings, axially split single stage pump. With more than 100 different hydraulics, the DVSH offers unmatched coverage for dependable operation with thousands of units deployed globally. |

With tens of thousands of units in operation around the world, the DVSH is the undisputed between bearings, axially split, single stage pump of choice. Fully compliant with the latest ISO 13709/API 610 (BB1) standards, the DVSH is particularly well-suited for use in process charge, transfer and pipeline services where uncompromising reliability over wide flow ranges is of utmost importance.

Flowserve DVSH Between Bearings Pump Applications

Crude, Product and CO2 Pipeline, Nuclear Service, Dewatering and Water Supply (mining), Drilling and Production, LNG, Renewable Fuel Production, Water Supply and Distribution (water), Auxiliary Services (power), Distillation (oil and gas), FPSO, Auxiliary (chemical), Cooling Water (power), Gas Treating and Sulfur Recovery, Boiler Feed (pulp and paper), Gas to Liquids, Boiler Feed Booster, Heavy Oil, Oil Sands and Shale, Condensate Extraction, Offsites and Waste Treatment

- Industries:

Chemical Processing, Mining, Water Resources, Power Generation, Pulp and Paper, Oil and Gas - Standards:

API682, API610

Flowserve DVSH Between Bearings Pump Benefit

- Double Volute, Axially Split Casing Design minimizes hydraulic radial forces in any condition down to the minimum flow.

- Suction and Discharge Nozzles are integrally cast in the lower casing half to permit pump disassembly without disturbing the piping.

- Near Centerline Mounting provides superior pump alignment and performance at elevated temperatures.

- Double Suction Impeller provides hydraulic axial balance and allows minimal NPSHr.

- ISO 21049/API 682 Seal Chambers ensure ample flow around the seal faces and accommodate numerous seal designs.

- Heavy-Duty Shaft Design ensures trouble-free operation below the first critical speed.

- Standard Renewable Casing and Impeller Wear Rings provide hydraulic stability and high operating efficiency.

Flowserve DVSH Between Bearings Pump-Axially Split, API, Single Case Operating Parameters

- Flows to 12 000 m3/h (52 835 gpm)

- Heads to 565 m (1854 ft)

- Pressures to 150 bar (2175 psi)

- Temperatures to 200°C (400°F)

- Speeds to 6000 rpm