Flowserve Centrifugal Pump Catalogue

Ensure safe and efficient operation across power generation, chemical, oil and gas and water treatment with reliable Flowserve pump technology. Our team provides tailored recommendations and technical support to match your exact application needs. Request a quote now to get started.

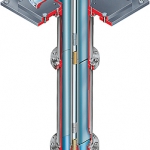

Flowserve DVSR Between Bearings Pump

Flowserve DVSR Between Bearings Pump

The Flowserve DVSR pump is a horizontally split, multistage, between bearings centrifugal pump engineered for high-pressure fluid transfer in critical industrial applications. Designed to meet demanding performance requirements, the DVSR delivers reliable operation in high head, high flow systems such as boiler feed, condensate transfer, reverse osmosis and water injection services.

With its between-bearings design, the DVSR ensures superior rotor stability, extended bearing life and smooth operation under high differential pressures. The pump features a modular construction for ease of maintenance and is available in a variety of metallurgies for compatibility with aggressive fluids and elevated temperatures.

Compliant with major international standards, the Flowserve DVSR is a preferred choice across power generation, oil & gas, petrochemical and industrial water treatment sectors.

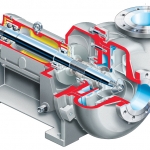

INNOMAG TB-MAG Fluoropolymer-Lined, Magnetic Drive ISO/ASME (ANSI) Chemical Process Pump

INNOMAG TB-MAG Fluoropolymer-Lined, Magnetic Drive ISO/ASME (ANSI) Chemical Process Pump

The INNOMAG TB-MAG is a sealless magnetic-drive pump with a fully encapsulated ETFE lining, engineered for leak-free handling of highly corrosive and hazardous fluids. Conforming to ISO 2858 and ASME B73.3 dimensions, it offers global installation flexibility.

Its magnetically coupled design eliminates mechanical seals, reducing maintenance and fugitive emissions. Ideal for acids, solvents, caustics and other aggressive chemicals in industries such as chemical processing, semiconductors, pharmaceuticals and water treatment.

With easy installation, high hydraulic efficiency and proven reliability, the TB-MAG meets the most demanding non-metallic pumping requirements.

PVML-Mag API 685, Overhung, Vertical In-line, Magnetic Drive Pump

PVML-Mag API 685, Overhung, Vertical In-line, Magnetic Drive Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The PVML-Mag is a sealless, magnetic drive vertical in-line pump designed in full compliance with API 685 standards for the reliable and safe transfer of flammable, toxic and hazardous fluids. With an overhung, vertical in-line configuration, it offers a compact footprint and simplified piping, making it ideal for space-constrained installations in refineries, chemical plants and petrochemical facilities. This pump eliminates mechanical seals, significantly reducing the risk of leaks and fugitive emissions. The magnetic drive system ensures complete containment of the process fluid, making it a perfect fit for critical services requiring zero leakage and API compliance. Available in various metallurgies and engineered for high reliability and low maintenance, the PVML-Mag offers long-term performance in demanding process environments. |

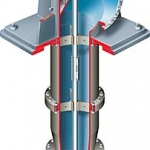

CVP, Concrete Volute Pump (BSP & BCV) Vertical

CVP, Concrete Volute Pump (BSP & BCV) Vertical

Brand |

Description |

| Flowserve | The CVP (BSV and BCV) Vertical Concrete Volute Pumps are engineered for high-efficiency and durability. These pumps are designed to handle demanding applications in various industries, offering optimal performance for both large-scale water and wastewater projects. The vertical design ensures a compact footprint while maintaining a high flow capacity, making them ideal for tight spaces. With advanced features and robust construction, these Concrete Volute Pumps are reliable solutions for managing high-volume pumping needs. |

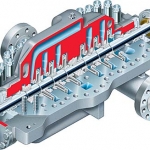

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

Brand |

Description |

| Flowserve | The Flowserve DMX is an axially split, multistage pump designed to DMX ISO 13709/API 610 (BB3), latest edition. DMX pumps are particularly suited for high-pressure applications, delivering reliable performance and efficiency in demanding environments. |

BP Diffuser Casing, Multistage, Process Barrel Pump ISO 13709/API 610 (BB5)

| Brand: | Flowserve |

|---|---|

| Description: | Fully compliant with ISO 13709/API 610 (BB5), this diffuser-style, double-case multistage pump is ideal for high-pressure applications in oil & gas, power generation and chemical processing. Precision-cast internals deliver superior efficiency, durability and reliability. |

Hydraulic Decoking Systems Control Valve

Hydraulic Decoking Systems Control Valve

| Brand: | Flowserve |

|---|---|

| Description: |

The Hydraulic Decoking Systems Control Valve is a critical component used in delayed coking units (DCUs) to safely and efficiently manage the high-pressure, high-temperature flow of cutting water, steam or coke slurry during the decoking cycle. Designed for extreme service conditions, these valves offer precise modulation, erosion resistance and fail-safe actuation to ensure uninterrupted operation in hydraulic decoking systems. Engineered for high cycle life and severe duty, the valve features robust trim designs, advanced coatings and materials compatible with coke fines, flashing fluids and thermal shock. It is commonly paired with hydraulic actuators and interlock systems for remote and automated control of decoking cutting tools, water jets or coke drums. Ideal for refineries, oil sands and petrochemical plants, this control valve ensures safe coke drum operation, minimizes downtime and protects downstream equipment from thermal and mechanical damage. |

| Brand: | Flowserve |

|---|---|

| Description: |

The Molten Salt VTP Pump is a vertical turbine pump specifically engineered for the safe and efficient handling of molten salts at extremely high temperatures, typically ranging between 290°C and 600°C. Designed for applications in concentrated solar power (CSP) plants, thermal energy storage systems and industrial heat transfer processes, this pump provides reliable performance where standard pumps would fail due to thermal stress. Featuring high-temperature metallurgy, thermal barriers and special shaft sealing systems, the Molten Salt VTP Pump ensures minimal thermal deformation, low heat transfer to drive components and maximum system uptime. Its vertical, multistage construction allows for deep sump installation and consistent flow even in large-scale molten salt circuits. Ideal for solar farms, chemical plants and high-temperature storage systems, this pump supports efficient energy transfer, extended service intervals and minimal maintenance under the most challenging operating conditions. |

| Brand: | Flowserve |

|---|---|

| Description: |

The VCT Vertical Mixed Flow Pump is a high-capacity, low-to-medium head pump designed for large-volume water handling applications, including cooling water circulation, flood control, irrigation and seawater intake. With its vertical shaft and mixed-flow impeller design, the VCT delivers efficient performance where high flow and moderate head are required. Its compact bowl assembly, customizable materials and modular column construction make it suitable for both deep sump installations and open wet-pit applications. The VCT is engineered for continuous duty operation with excellent hydraulic stability, corrosion resistance and low vibration, making it ideal for municipal, industrial and utility-scale water systems. |

VTP Vertical Turbine, Wet Pit Pump

VTP Vertical Turbine, Wet Pit Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The VTP Vertical Turbine Pump is a wet pit, single or multistage vertical pump designed for continuous, high-capacity water and process fluid transfer. Installed in open wet wells or deep sumps, the VTP pump features a vertical shaft, mixed or radial flow impellers and modular column construction, making it ideal for applications that require deep setting, extended shaft lengths and high hydraulic efficiency. Built for use in power generation, water treatment, irrigation, seawater intake, flood control and industrial utilities, the VTP pump is available in a wide range of metallurgies and configurations to suit both clean and abrasive or corrosive fluids. The wet-pit design eliminates the need for priming and simplifies installation in submerged environments. |

Hydraulic Decoking Systems Drill Stem

Hydraulic Decoking Systems Drill Stem

Brand |

Description |

| Flowserve | Drill stems carry torque from the rotary joint to the cutting tool together with water. Extremely durable and with a side load strength four times higher than similar welded drill stem designs are Flowserve threaded drill stems. |

Hydraulic Decoking Systems AutoShift™ Cutting Tool

Hydraulic Decoking Systems AutoShift™ Cutting Tool

| Brand: | Flowserve |

|---|---|

| Description: |

The AutoShift™ Cutting Tool is an advanced, dual-function component in hydraulic decoking systems, designed to automatically switch between boring and cutting operations without manual intervention. Used in delayed coking units (DCUs), this tool enhances safety, reduces cycle time and improves operational efficiency by streamlining the decoking process. Built for use with high-pressure water systems, the AutoShift™ tool transitions between drill and cutting modes using internal hydraulic control, eliminating the need for tool retrieval or repositioning. This ensures continuous operation during the coke removal process, minimizing drum downtime and operator exposure. Engineered for high reliability in extreme temperature and pressure environments, the AutoShift™ Cutting Tool is a key component for fully automated, remote-controlled decoking systems in modern refineries. |

Hydraulic Decoking Systems Crosshead (Free Fall Arrestor)

Hydraulic Decoking Systems Crosshead (Free Fall Arrestor)

Brand |

Description |

| Flowserve | Flowserve Crosshead Free Fall Arrestor System is an advanced solution designed to enhance safety and efficiency in Hydraulic Decoking Systems. The Free Fall Arrestor System ensures that the cutting assembly in decoking operations is safely suspended and can be quickly stopped in case of rope tension failure, preventing damage to personnel and equipment. Flowserve’s technology is engineered for robust, high-performance operations in demanding industrial environments like petroleum refining and heavy oil upgrading. |

Brand |

Description |

| Flowserve | The Decoking System Winch is designed for coke cutting, controlling the cutting assembly by raising and lowering the cutting tool in the coke drum. It ensures safe and reliable operation under demanding conditions and is available with pneumatic, hydraulic or electric drive options, with electric-over-air controls for remote cutting. |

Hydraulic Decoking Systems Tensiometer / Load Cell

Hydraulic Decoking Systems Tensiometer / Load Cell

| Brand: | Flowserve |

|---|---|

| Description: |

The Tensiometer / Load Cell in a hydraulic decoking system is used to monitor the load applied to the drill stem and cutting tool assembly during coke removal in delayed coking units (DCUs). It provides real-time tension and weight feedback, enabling safe, automated control of vertical movement and detecting potential issues such as tool jams, excess load or free-fall conditions. Mounted between the decoking winch and crosshead or integrated into the lifting assembly, the load cell continuously measures the force exerted on the system, which is then used by the control system to prevent overloading, reduce mechanical stress and increase operational safety. The tensiometer/load cell is engineered for high-load, high-cycle refinery environments, offering accurate, drift-free performance under extreme temperatures, pressures and vibration, making it an essential component of modern automated or semi-automated decoking systems. |

Hydraulic Decoking Systems Latching Mechanisms

Hydraulic Decoking Systems Latching Mechanisms

| Brand: | Flowserve |

|---|---|

| Description: |

Latching mechanisms are critical components in hydraulic decoking systems, used to secure and release the drill stem, cutting tools and related assemblies during coke removal operations in delayed coking units (DCUs). These mechanisms ensure positive locking during vertical movement and allow for safe, controlled tool engagement or disengagement as part of the decoking cycle. Designed for high-load, high-cycle operation, latching mechanisms are integrated into crossheads, handling tools or lifting assemblies to prevent unintentional tool drops or misalignment. Built with precision machined parts, corrosion-resistant materials and fail-safe locking features, they support both manual and automated decoking systems in the most demanding refinery environments. By ensuring mechanical safety, alignment accuracy and ease of operation, these mechanisms play a vital role in reducing downtime, enhancing operator safety and increasing system reliability during the coke cutting process. |

Scorpion FLS 600 Drill Stem Tensioner

Scorpion FLS 600 Drill Stem Tensioner

| Brand: | Flowserve |

|---|---|

| Description: |

The Scorpion FLS 600 Drill Stem Tensioner is an advanced tension management device engineered for use in hydraulic decoking systems within delayed coking units (DCUs). Designed to monitor and maintain consistent tension on the drill stem, it enhances operator safety, prevents tool damage and improves overall system performance during coke cutting operations. With real-time feedback and integration into decoking control systems, the FLS 600 provides automated load adjustments, compensating for dynamic conditions such as tool binding, torque surges or sudden load drops. Its robust design handles high-load, high-cycle applications, withstanding extreme temperatures, pressure fluctuations and harsh refinery environments. The Scorpion FLS 600 is a key safety and performance component in fully automated or semi-automated hydraulic decoking systems, helping reduce downtime, extend tool life and increase operational precision. |

Hydraulic Decoking Systems Video Monitoring System

Hydraulic Decoking Systems Video Monitoring System

| Brand: | Flowserve |

|---|---|

| Description: |

The Video Monitoring System is an essential component of hydraulic decoking systems, providing real-time visual feedback during critical operations such as coke cutting, boring and tool positioning in delayed coking units (DCUs). Designed to operate in high-temperature, high-vibration and potentially hazardous environments, this system allows operators to monitor cutting tool performance, confirm tool alignment and respond quickly to abnormal conditions. Typically installed near the coke drum deck or tool guide, the system includes high-resolution, industrial-grade cameras, protective housings and remote viewing interfaces. It enhances both safety and process efficiency by reducing the need for direct operator exposure near active decoking equipment. Fully compatible with automated or semi-automated hydraulic decoking systems, this monitoring solution supports safer, faster and more controlled decoking cycles in refineries and petrochemical facilities. |

Hydraulic Decoking Systems Rotary Joint

Hydraulic Decoking Systems Rotary Joint

| Brand: | Flowserve |

|---|---|

| Description: |

The rotary joint enhances operational efficiency, safety and equipment life in automated and semi-automated decoking systems used across refineries and petrochemical plants worldwide. |

Hydraulic Decoking Systems Drill Stem Guide and Shroud Assembly

Hydraulic Decoking Systems Drill Stem Guide and Shroud Assembly

| Brand: | Flowserve |

|---|---|

| Description: |

The Drill Stem Guide and Shroud Assembly is an essential component in hydraulic decoking systems, engineered to provide accurate alignment, lateral support and mechanical protection for the drill stem and cutting tools during coke removal in delayed coking units (DCUs). Installed at the top of the coke drum or cutting deck, the guide and shroud ensure precise tool entry, minimize vibration and protect surrounding structures from high-pressure water and debris. The guide assembly maintains vertical alignment of the drill stem, preventing deflection and wear during boring and cutting, while the shroud acts as a protective barrier against spray and thermal effects. Constructed from corrosion- and heat-resistant materials, the assembly is designed for long service life in high-temperature, high-cycle refinery environments. Ideal for manual and automated decoking systems, the Drill Stem Guide and Shroud Assembly enhances cutting accuracy, safety and system longevity. |

Hydraulic Decoking Systems Audio Monitoring System

Hydraulic Decoking Systems Audio Monitoring System

| Brand: | Flowserve |

|---|---|

| Description: |

The Audio Monitoring System is a specialized component in hydraulic decoking systems, designed to provide real-time acoustic feedback during coke cutting and boring operations in delayed coking units (DCUs). This system helps operators detect key process sounds such as tool contact, cutting performance, blockages or free-fall conditions, which may not be visible through standard video monitoring alone. Installed near the cutting deck or coke drum, the system includes high-sensitivity industrial microphones with noise-canceling and filtering features, ensuring clear, actionable audio in high-noise refinery environments. The system can be integrated with decoking control panels or remote operation consoles, enabling enhanced situational awareness, safety and predictive maintenance. By capturing subtle changes in sound signatures, the Audio Monitoring System supports faster operator response, reduced risk of tool damage and more efficient decoking cycles. |

Hydraulic Decoking Systems Coke Drum Monitoring

Hydraulic Decoking Systems Coke Drum Monitoring

Brand |

Description |

| Flowserve | The Flowserve HDS Hydraulic Decoking System improves oil refining safety and efficiency by monitoring coke drums in real-time and confirming total coke removal. The technology minimises downtime, operator exposure and provides consistent decoking cycles. This technology is essential for hydraulic decoking systems, the Flowserve HDS and process improvement in oil refining. |

Brand |

Description |

| Flowserve |

|

SealSentry™ CRC Seal Chambers for ASME (ANSI) Process Pumps

SealSentry™ CRC Seal Chambers for ASME (ANSI) Process Pumps

| Brand: | Flowserve |

|---|---|

| Description: |

SealSentry™ CRC Seal Chambers are purpose-built to address the limitations of conventional seal housings in ASME (ANSI) process pumps. Whether you’re dealing with slurries, chemical contaminants or elevated temperatures, this chamber design helps maintain a controlled, turbulence-free environment around the mechanical seal, extending seal life and boosting system reliability. Its tapered bore geometry minimizes radial pressure drop while enhancing fluid circulation around the seal faces. Unlike traditional straight-bore chambers, the CRC design promotes efficient heat dissipation, reduces solids buildup and supports API flush plans such as Plan 11, 21 and 23. The result? Fewer unplanned shutdowns and a longer mean time between seal failures. Ideal for use in refineries, chemical plants and industrial fluid systems, the SealSentry™ CRC offers an easy upgrade path for Flowserve ANSI pumps and other standard process pump platforms. |

PVML ISO 13709/API 610 (OH5) Vertical In-Line Overhung API Process Pump

PVML ISO 13709/API 610 (OH5) Vertical In-Line Overhung API Process Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The PVML is a vertical in-line, overhung process pump designed to meet the rigorous specifications of ISO 13709/API 610 OH5. Developed for refineries, petrochemical plants and industrial process systems where floor space is limited but reliability is non-negotiable, the PVML combines a compact footprint with API-grade performance. Its in-line design simplifies piping and eliminates the need for special foundations, while the single, rigid bearing housing ensures shaft alignment and stability during high-speed operation. Optimized for continuous-duty applications, the PVML is engineered for clean or lightly contaminated fluids across a wide range of temperatures and pressures. Whether installed in pump trains or as a standalone unit, the PVML delivers low vibration, high efficiency and full API compliance , making it a dependable choice for vertical pumping in critical services. |

BF and BFD Between Bearings, Axially Split Multistage Pumps

BF and BFD Between Bearings, Axially Split Multistage Pumps

| Brand: | Flowserve |

|---|---|

| Description: |

The BF and BFD pump models are between bearings, axially split multistage pumps engineered for high-pressure fluid transport in power generation, pipeline, water injection and boiler feed services. With a rugged construction and precision-balanced rotor assembly, these pumps are built to perform reliably under continuous-duty, high-head conditions. Both models feature axially split casings that simplify inspection and maintenance, allowing quick access to internal components without disturbing pipe connections or motor alignment. The BF series is typically used for applications with lower flow but higher pressure, while the BFD model supports larger flow volumes with the same robust multistage design. Manufactured to meet global standards including ISO and API equivalents, the BF and BFD pumps provide exceptional efficiency, low vibration and high mechanical integrity across the most demanding industrial applications. |

PVXM ISO 13709/API 610 (OH3) Vertical In-Line Overhung API Process Pump

PVXM ISO 13709/API 610 (OH3) Vertical In-Line Overhung API Process Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The PVXM is a vertical in-line, overhung process pump conforming to ISO 13709/API 610 OH3 standards, designed for applications requiring API reliability in a vertical configuration. With a space-saving, centerline-mounted design, the PVXM is ideal for installations where floor space is limited but robust mechanical performance is essential. Unlike OH5 designs, the PVXM features a separate bearing frame and rigid shaft support, providing improved stability, lower vibration and enhanced seal life. This makes it especially well-suited for hydrocarbon processing, chemical manufacturing and refinery utility services. Available in a range of metallurgy options, the PVXM supports high-temperature fluids, clean or slightly contaminated liquids and API flush plans. It delivers high efficiency and ease of maintenance while meeting stringent API requirements for continuous-duty, mission-critical pumping systems. |

| Brand: | Flowserve |

|---|---|

| Description: |

Pulley Blocks and Sheaves are critical components used in lifting, hoisting and rigging systems across industrial, construction and energy sectors. Designed to redirect or multiply the force of a load, these components are essential for safe and efficient handling of heavy equipment, particularly in vertical motion applications like crane systems, hydraulic decoking winches and material hoists. Pulley blocks consist of one or more sheaves (grooved wheels) enclosed in a frame, allowing ropes, chains or cables to move smoothly with minimal friction. Sheaves are available in a variety of sizes, load ratings and materials, including cast steel, bronze and composite alloys to accommodate different wire rope diameters and working conditions. Engineered for high load capacity, durability and minimal maintenance, pulley blocks and sheaves ensure precise load control and reduced stress on winch systems and lifting structures. Whether used in refineries, construction sites, offshore rigs or manufacturing facilities, these components help ensure safe, reliable load transfer under extreme conditions. |

| Brand: | Flowserve |

|---|---|

| Description: |

The MVX Solids Handling Pump is a wet pit vertical pump engineered for the reliable transfer of solids-laden fluids, industrial slurries and municipal wastewater. Designed for installation in open sumps or wet wells, the MVX offers robust hydraulic performance, superior solids passage and long service life in tough operating environments. With a fully recessed impeller and wide passages, the MVX minimizes clogging and abrasion, making it ideal for handling fibrous materials, grit and debris found in sewage, stormwater or industrial process waste. The vertical configuration allows for deep sump installation, while eliminating the need for priming or submersible components. Built with abrasion- and corrosion-resistant materials and available with optional column bearings, wear rings and flush systems, the MVX pump is a durable and efficient solution for high-solids wet pit applications in power, pulp & paper, chemical, food processing and municipal treatment plants. |

Brand |

Description |

| Flowserve | Flowserve decoking hoses are engineered to withstand the challenging conditions of delayed coker units (DCU). These high-pressure hoses are resistant to oil and chemicals and are equipped with abrasive-resistant outer covers and multiple layers of wire reinforcement, ensuring exceptional strength and long-lasting durability. |

Flowserve DVSH Between Bearings Pump

Flowserve DVSH Between Bearings Pump

Brand |

Description |

| Flowserve | Designed for continuous operation in heavy duty pipeline services, the DVSH is a between bearings, axially split single stage pump. With more than 100 different hydraulics, the DVSH offers unmatched coverage for dependable operation with thousands of units deployed globally. |

PHL ISO 13709/API 610 (OH2) Centerline Mounted Process Pump

PHL ISO 13709/API 610 (OH2) Centerline Mounted Process Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The PHL is a single-stage overhung process pump designed in full compliance with ISO 13709 and API 610 (OH2) standards. With a centerline-mounted casing, the pump delivers superior performance in high-temperature and high-pressure services by minimizing thermal misalignment and maintaining mechanical alignment during extreme conditions. Ideal for refineries petrochemical facilities and power plants, the PHL offers a back pull-out design for easy maintenance without disturbing the piping or motor. It features a heavy-duty shaft rigid bearing frame and a wide range of API flush plan options to handle aggressive fluids at elevated temperatures. Whether moving hydrocarbons corrosive chemicals or heat transfer media the PHL provides exceptional reliability in continuous-duty applications where uptime and mechanical resilience are critical. |

| Brand: | Flowserve |

|---|---|

| Description: | The LC chemical slurry pump is a horizontally orientated, frame-mounted, single-stage, end-suction configuration featuring a tangential discharge nozzle. It is designed to endure the demands of abrasive and corrosive applications. |

MPT Self-Priming, Overhung, Solids Handling Pump

MPT Self-Priming, Overhung, Solids Handling Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The MPT is a self-priming overhung centrifugal pump engineered to handle solids-laden and abrasive fluids in industrial and municipal services. Designed for above-grade installation, the MPT eliminates the need for priming systems or submerged suction lines, making it ideal for wastewater lift stations stormwater drainage sludge pits and chemical sump applications. Its robust casing and semi-open impeller allow for efficient solids handling and reduced clogging while the back pull-out design enables quick servicing without disturbing suction or discharge piping. With its ability to reprime automatically after the sump drains, the MPT is well-suited for intermittent flow conditions and emergency bypass systems. Available in multiple materials and configurations, the MPT offers long-lasting performance in harsh environments where uptime and easy access matter most. |

MNR and MND Overhung Absorber Recirculation Pumps

MNR and MND Overhung Absorber Recirculation Pumps

| Brand: | Flowserve |

|---|---|

| Description: |

The MNR and MND pumps are overhung end suction centrifugal pumps specifically developed for absorber recirculation in flue gas desulfurization (FGD) systems. Designed for continuous-duty operation in abrasive and corrosive slurry environments, these pumps provide reliable performance in power generation and industrial gas scrubbing applications. The MNR model features a radially split casing with top suction and top discharge nozzles for simplified piping and maintenance. The MND variant includes a volute casing design with side suction for flexible layout options. Both designs offer large solids passage, thick wear-resistant components and are available in rubber-lined or high-chrome iron construction to extend pump life in harsh conditions. With high efficiency low maintenance requirements and excellent hydraulic stability the MNR and MND pumps are trusted in FGD systems around the world. |

| Brand: | Flowserve |

|---|---|

| Description: |

The MP1 Multiphase Screw Pump is a twin-screw positive displacement pump designed to transport crude oil gas water and solid mixtures in upstream oil and gas production. Capable of handling high gas volume fractions without separation, the MP1 is ideal for multiphase boosting gathering lines and wet gas compression in remote or unmanned operations. The pump’s axially balanced screw design ensures smooth pulsation-free flow while maintaining consistent volumetric efficiency across a wide range of flow conditions. With excellent suction capability and the ability to tolerate entrained solids, the MP1 eliminates the need for phase separation upstream, reducing infrastructure cost and complexity. Built to API 676 standards and available in a variety of metallurgies, the MP1 offers reliable long-term performance in harsh production environments including onshore offshore and FPSO platforms. |

Brand |

Description |

| Flowserve | The Flowserve AFV axial flow suspended shaft vertical pump is a single-stage propeller type design. This family of pumps is engineered to meet the demanding requirements of nuclear power plant pumps, offering reliable performance and efficiency as part of the comprehensive Flowserve CAV Nuclear Pump line, tailored for nuclear industry solutions. |

AFV Vertical, Axial Flow Wet Pit Pump

AFV Vertical, Axial Flow Wet Pit Pump

| Brand: | Flowserve |

|---|---|

| Description: |

|

MSP Vertical In-Line, Medium Speed, Overhung API Process Pump

MSP Vertical In-Line, Medium Speed, Overhung API Process Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The MSP pump is a vertical in-line overhung process pump developed to meet API 610 (OH6) requirements for medium speed operation in critical oil gas and chemical services. With a design that combines the footprint efficiency of an OH5 with the shaft stability of an OH2, the MSP delivers superior performance in applications that demand low vibration low NPSH and extended seal life. The integrated bearing bracket and thrust bearing arrangement provide excellent rotor stability at speeds up to 4000 rpm while the close-coupled design eliminates alignment issues and simplifies installation. This makes the MSP ideal for booster services pipeline recirculation and light hydrocarbon transfer. Offered in a wide range of metallurgy and API flush plan compatibility, the MSP is built for continuous-duty operation in high temperature and high reliability environments. |

ME Overhung, End Suction Industrial Process Pump

ME Overhung, End Suction Industrial Process Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The ME pump is a horizontal overhung end suction centrifugal pump engineered for general industrial fluid handling in applications that require dependable performance with low installation and maintenance costs. Designed to ISO 2858 dimensional standards, the ME pump is suitable for water services light chemicals cooling systems and auxiliary plant processes across a wide range of industries. Its modular back pull-out design enables fast and easy maintenance without disturbing pipework or motor alignment. With a wide range of sizes materials and sealing options, the ME pump offers flexibility for clean or slightly contaminated fluids in non-API environments. Compact robust and efficient, the ME pump is a reliable solution for non-critical services in manufacturing utilities food and beverage and general processing plants. |

Mark 3 Group 4 Chemical Process Pump

Mark 3 Group 4 Chemical Process Pump

| Brand: | Flowserve |

|---|---|

| Description: |

The Mark 3 Group 4 is part of Flowserve’s industry-leading ANSI chemical process pump family, specifically designed to handle higher flow and head combinations beyond the standard range of Group 1 to Group 3 sizes. With a horizontal overhung back pull-out design, Group 4 pumps offer exceptional hydraulic coverage for demanding applications in the chemical processing refining pharmaceutical and general industrial sectors. Built to comply with ASME B73.1 dimensional standards, the Mark 3 Group 4 features a robust shaft and bearing arrangement that delivers long-term reliability even under corrosive high-pressure conditions. It supports a wide range of materials and sealing plans, making it ideal for aggressive acids solvents and slurries. As part of the Mark 3 family, this pump ensures consistent performance across system expansions without compromising on efficiency or maintainability. |

Looking for advanced Flowserve pumps designed for high-pressure, corrosive or hazardous fluid handling? From between bearings multistage pumps to sealless magnetic drive and vertical turbine pumps, our specialists can help you choose the right solution for your industry. Contact us today for expert guidance.

Didn’t find the specific pump model you are looking for? Visit our main product page to explore the complete range of Flowserve and Worthington pumps available.