CPX ISO Overhung, Single Stage Process Pump

CPX ISO Overhung, Single Stage Process Pump

CPX ISO Overhung, Single Stage Process Pump

| Brand: | IDP |

|---|---|

| Description: |

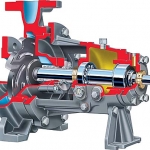

The Flowserve CPX is a horizontal, overhung, single-stage process pump designed to conform to ISO 2858 dimensional and ISO 5199 design criteria. Incorporating advanced features for improved reliability and ease of maintenance, the CPX chemical process pump is ideal for handling corrosive and aggressive fluids in chemical processing, pharmaceuticals, pulp and paper and general industrial applications. With its precision-engineered hydraulics, rigid shaft design and heavy-duty bearing system, the CPX delivers long-lasting performance in continuous-duty operations. |

Conforming to ISO 2858 dimensional and ISO 5199 design criteria and incorporating advanced features, the CPX chemical process pump provides unmatched performance and reliability. This ruggedly designed pump offers significant operational and maintenance enhancing benefits to minimize the total cost of pump ownership.

CPX ISO Pump Applications

Agriculture, Shipping, Slurry Processing, Acid Transfer, Electronics, Volatile Organic Compounds, Waste Processing, FPSO, Water Supply and Distribution (water), Gas Treating and Sulfur Recovery, Water Supply and Treatment (oil and gas), Water Treatment, HVAC, Heavy Oil, Oil Sands and Shale, Automotive, Hydraulic Press (metals), Pharmaceuticals, Auxiliary (chemical), LNG, Polymers, Auxiliary Services (power), Leaching Acid, Bleach Chemical (pulp and paper), Nuclear Service, Solvents, Chemical and Liquor (pulp and paper), OEM, Caustic and Chlor-alkali, Coatings (pulp and paper), Offsites and Waste Treatment, Food Processing, Construction, Plating, Galvanizing and Other Coatings, Cooling Water (metals), Renewable Fuel Production, Sewage Collection and Treatment, Dewatering and Water Supply (mining), Drilling and Production

- Industries:

Chemical Processing, General Industries, Pulp and Paper, Power Generation, Mining - Standards:

ISO

Advanced 45° Conical Seal Chamber with integral vortex flow modifiers increases mechanical seal life.

Standard Non-Contacting Labyrinth Seals keep lubricants in and contaminants out.

Heavy-Duty Pump End and Drive End Bearings selected for long life and reliability.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads and improves reliability.

External Three Bolt Rotor Adjustment allows impeller clearances to be reset in situ, thereby restoring head and efficiency.

One-Piece, Ductile Iron Bearing Housing is designed for maximum strength and safety as well as tight concentricity and alignment.

Back Pullout Design allows removal of rotating element without removing casing, piping or motor.

Operating Parameters

- Flows to 1400 m3/h (6160 gpm)

- Heads to 220 m (720 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -80C (-110F) to 350C (660F)

CPX, CPXR, CPXN and CPXP Pump User Instructions

Handling corrosive or hazardous fluids? The CPX pump is built for ISO-standard reliability with minimal maintenance. Talk to us about specifying the right CPX configuration for your chemical or industrial process.