Bellows

The bellows design overcomes many of the problems associated with pusher designs. The absence of a dynamic gasket eliminates the possibility of “hand-up”, caused by build-up of deposits or gasket swell.

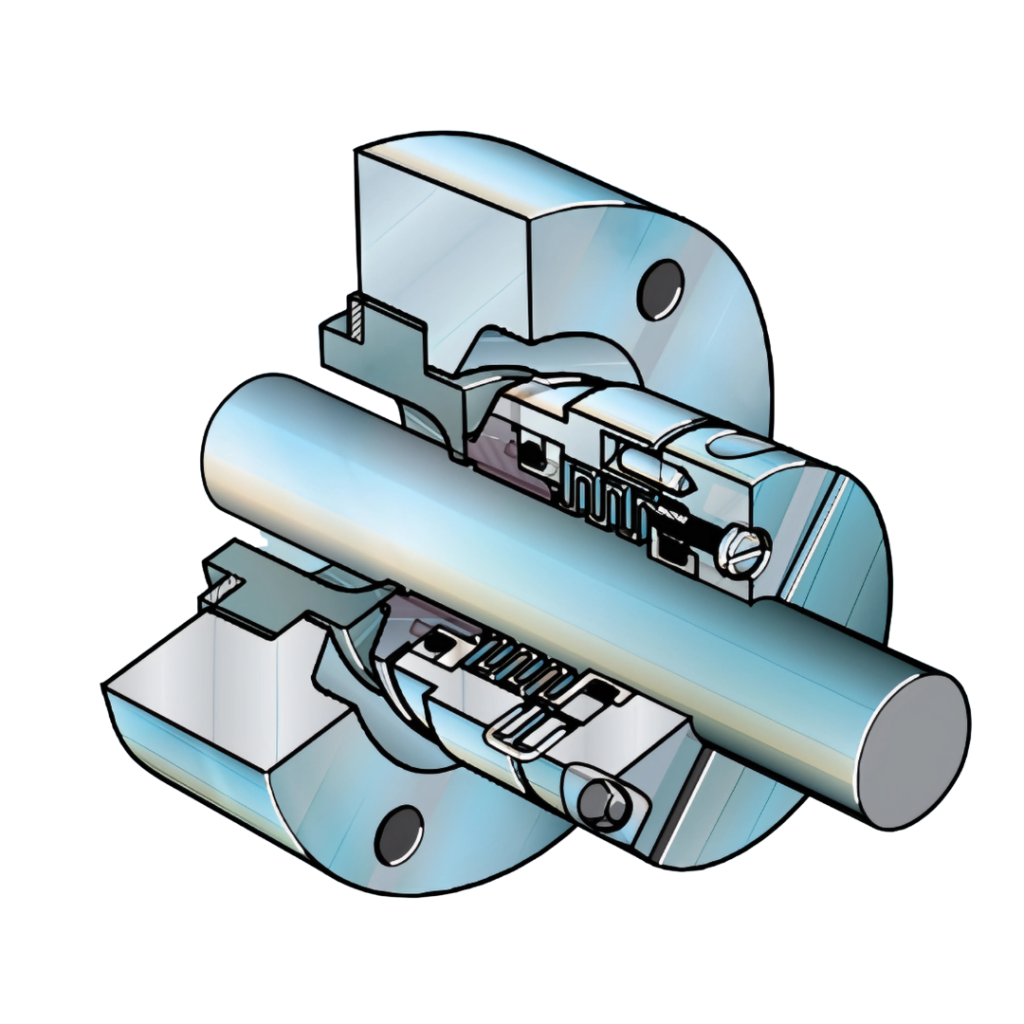

Flowserve GCX Seal

Flowserve GCX Seal

| Brand | Flowserve |

|---|---|

| Description | The Flowserve GCX is a self-contained, single cartridge mechanical seal engineered for multiple chemical exposure environments. Built to handle intermediate and batch chemical processes, this seal ensures reliable performance and long service life. |

GCX Seal Key Features

-

Standards: ASME (ANSI) compliant

-

Designed for chemical processing environments with varying conditions

-

Ideal for intermediate and batch chemical applications

-

Incorporates graphite secondary seals for added chemical resistance and reliability

-

Compact cartridge design for easy installation and maintenance

Pac-Seal Type 51 and 52 Seals

Pac-Seal Type 51 and 52 Seals

| Brand | Pac-Seal |

| Description |

Pac-Seal Type 51 and 52 mechanical seals are designed for narrow cross-section seal bores and meet international standards including ISO, ASME (ANSI), and DIN24960. They offer high performance and flexibility for a wide range of applications, making them ideal replacements for Crane Type 1 and Type 2 seals. These seals feature a bellows design that allows greater axial movement and shaft deflection compared to Type 21. Both Type 51 and Type 52 are available in balanced versions and double seal configurations to suit demanding industrial environments. |

Pac-Seal Type 51 and 52 Seals Applications

Marine, chemical processing, wastewater treatment, petroleum production and refining

Standards:

ISO, ASME (ANSI), DIN24960

Pac-Seal Type 51 and 52 Seals Key Features

-

Designed for ANSI and DIN 24960 seal bores

-

Greater axial movement and shaft deflection than Type 21

-

Available in balanced and double seal configurations

-

High-quality replacement for Crane Type 1 (Type 51) and Type 2 (Type 52)

-

Suitable for high pressure and high-speed applications

Materials:

Buna-N, carbon, ceramic, 316 stainless steel

Performance Specifications:

-

Pressure: 600 psi / 41.5 bar (balanced)*

-

Temperature: up to 240°F / 115°C

-

Speed: up to 6000 fpm / 30.5 m/s (Type 51)

-

Sizes: 0.652 mm to 3.25 mm

*Note: With COOLCARB face, temperature range is extended to –40 to 200°F (–40 to 93°C)

PAC-SEAL Replacement Seal Division

Pac-Seal Replacement Seal Catalogue

Looking for a high-quality replacement seal? Pac-Seal Type 51 and 52 mechanical seals provide reliable performance across a range of demanding applications. Contact us today to confirm compatibility, request specifications or get a quote from our team.

Pac-Seal Type 68 Seals

Pac-Seal Type 68 Seals

Pac-Seal Type 68 is a premium mechanical seal designed for applications such as water systems, well systems, oil production, and general-purpose pumping. It is commonly used in circulating water, pool, and spa systems. This unit features a spring-loaded portion that is pressed into the pump housing while the ceramic mating ring rotates with the shaft. The standard Type 68 includes an in-house molded phenolic material, a graphite-rich plastic, that provides intermittent dry-run capability. This makes it especially reliable for pool and spa environments. Pac-Seal Type 68 is a high-quality replacement for Crane Type 6A, offering enhanced durability and performance in demanding conditions.

Pac-Seal Type 68 Seals Features and Technical Specifications

Applications:

Water systems, well applications, oil production, general-purpose pumping, circulating water, pool, and spa systems

Installation:

Spring-loaded portion pressed into pump housing, ceramic mating ring rotates with the shaft

Key Materials:

-

Buna-N

-

COOLCARB® carbon

-

Ceramic

-

304 Stainless Steel

-

Brass outer shell available

Performance Ratings:

-

Pressure: up to 75 psi (5 bar balanced)

-

Temperature: up to 400°F (204°C)

-

Speed: up to 15,000 fpm (76.6 m/s)

-

Sizes: 0.312 mm to 1.0 mm

Special Notes:

With COOLCARB® face: -40°F to 200°F / -40°C to 93°C

PAC-SEAL Replacement Seal Division

Pac-Seal Replacement Seal Catalogue

Looking for a reliable replacement for your Crane Type 6A seal? Choose the Pac-Seal Type 68 for unmatched dry-run capability, high-speed endurance and long-term performance in pool, spa and industrial applications. Contact us today to request a quote or technical datasheet, our team is ready to assist you with selection and installation support.

Flowserve TBR PTFE Bellows Seal

Flowserve TBR PTFE Bellows Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve TBR is a high-performance PTFE bellows mechanical seal developed for corrosive and aggressive chemical applications. Designed for outside mounting, the TBR eliminates issues typically associated with elastomer secondary seals, such as shaft fretting and packing hang-ups. Crafted from nonmetallic PTFE materials, the TBR is ideal for use in environments that involve volatile chemicals, acids, slurries and pharmaceutical-grade processes. Its proven reliability makes it a popular sealing solution across multiple industries. |

TBR PTFE Bellows Seal Features and Applications

Key Industries:

-

Waste Processing

-

VOC (Volatile Organic Compounds) Handling

-

Solvent Applications

-

Slurry Processing

-

Polymers and Plastics

-

Caustic and Chlor-Alkali Systems

-

Acid Transfer

-

Auxiliary Chemical Services

-

Pharmaceutical Manufacturing

Key Features:

-

Nonmetallic PTFE construction

-

Outside-mounted bellows configuration

-

Excellent resistance to chemical attack

-

Eliminates common elastomer issues such as shaft wear and packing hang-up

-

Suitable for high-purity and corrosive fluid transfer

Looking for a reliable chemical seal for aggressive media? The Flowserve TBR PTFE Bellows Seal is your go-to solution for applications involving corrosive acids, volatile solvents and high-purity requirements. Reach out now to request a quote, technical consultation or full documentation, our team is ready to help you select the right seal for your system.

Flowserve GTSP Seal

Flowserve GTSP Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve GTSP is a high-performance gas seal engineered for extreme temperature applications in refinery and hydrocarbon processing. Designed with a dual pressurized configuration, this metal bellows seal excels in environments such as alkylation, catalytic cracking, hydrocracking and other high-heat upstream and downstream operations. Built with Alloy 718 welded metal bellows, the GTSP offers superior resistance to stress corrosion cracking, particularly in sulfuric-laden services. Its bi-directional wavy face topography creates a gas film barrier between seal faces, enabling non-contacting performance, lower drag and minimal energy consumption. Whether pressurized with dry steam or nitrogen, this seal delivers long-term reliability and reduced lifecycle cost. |

GTSP Seal Applications and Industries

Target Applications:

-

High-temperature process pumps

-

Dual containment sealing for hazardous hydrocarbons

-

Non-contacting operation in high-speed rotating equipment

Industries:

-

Alkylation

-

Catalytic Cracking

-

Crude Handling & Treatment

-

Distillation

-

Heavy Oil Upgrading

-

Hydrocracking

-

Hydrotreating

-

SAGD (Steam Assisted Gravity Drainage)

Technical Highlights

-

Dual pressurized configuration with dry steam or nitrogen

-

Bi-directional wavy face topography for non-contacting seal faces

-

Alloy 718 welded metal bellows construction

-

Optimized for high-temperature, high-pressure, and corrosive chemical exposure

-

Designed to maximize equipment uptime and minimize energy costs

Handling extreme temperature and corrosive hydrocarbon media? The Flowserve GTSP Seal is engineered for the harshest operating conditions in the refining and petrochemical industries delivering non-contacting performance, maximum uptime and long-term cost efficiency. Get in touch today to request a datasheet, consultation or product quotation. Our experts are ready to support your application requirements.

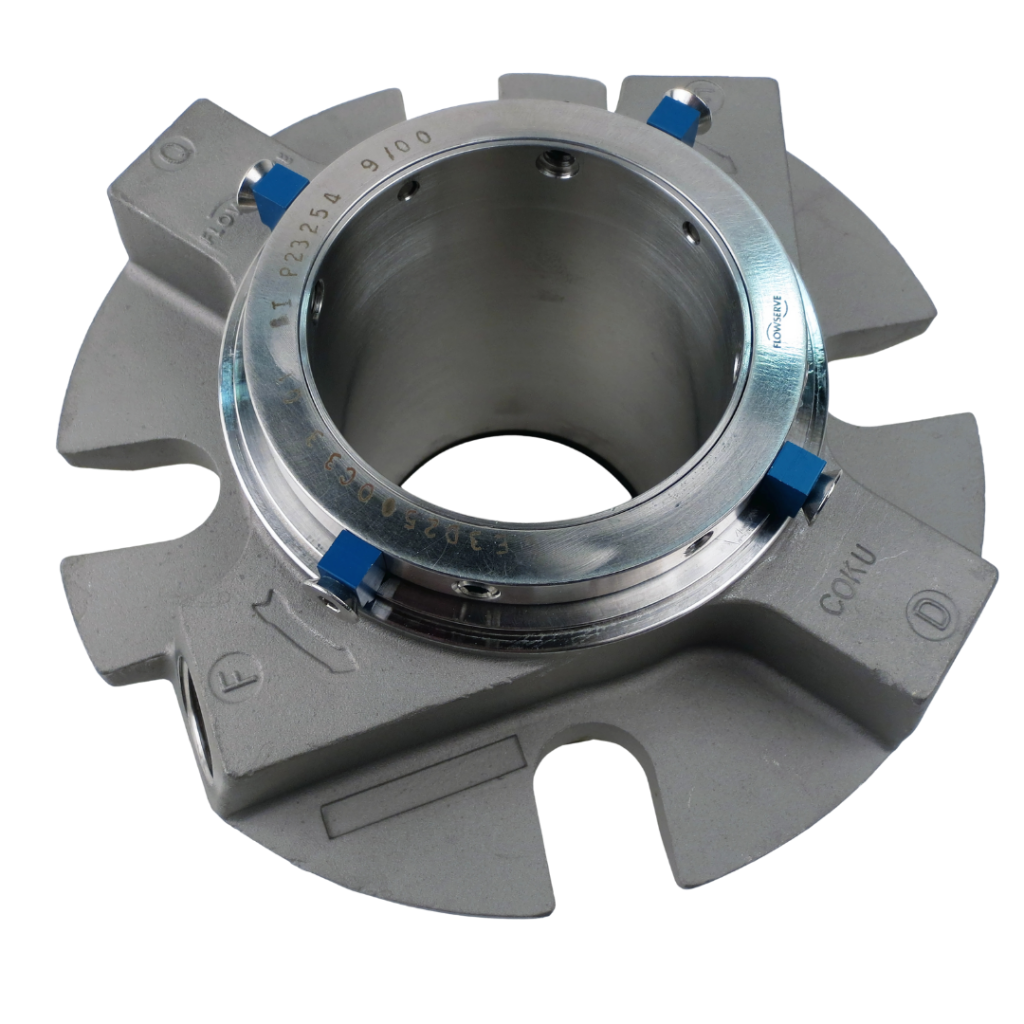

Flowserve ISC2 Series Cartridge Seals

Flowserve ISC2 Series Cartridge Seals

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve ISC2 Series is a comprehensive family of standardized cartridge seals engineered for maximum reliability, flexibility and interoperability across a wide range of pump models and applications. Built to meet API 682, ASME (ANSI), DIN 24960 and ISO standards, ISC2 seals are ideal for facilities seeking to reduce inventory, streamline maintenance and improve uptime across multiple systems. From general-purpose to toxic and high-demand services, ISC2 seals are designed to last, even under dry running, frequent cycling, and off-design conditions. |

ISC2 Applications and Industries

Applications:

-

Pipeline

-

Power Generation

-

Pulp and Paper

-

Agricultural Chemicals

-

Synthetic Production

-

Bioprocessing

-

Tank Farm Transfer

-

Chemical Processing

-

Toxic Services

-

Wastewater and Condensate

-

Light Oils and Slurries

-

Organic and Inorganic Chemicals

-

Petrochemical and Hydrocarbon Processing

Industries Served:

-

Agriculture

-

Chemical and Liquor

-

Tank Farms and Logistics

-

Pharmaceuticals

-

Paper Stock and Pulp

-

Pipeline Products

-

General Industrial Applications

Key Features and Benefits

-

Full API 682 compliance for industry-standard performance

-

Robust face drive mechanism improves reliability during variable operation

-

Dry-run capable thermal management increases seal longevity

-

High-efficiency barrier fluid circulation for enhanced cooling

-

Rigid setting devices ensure consistent installation

-

Standardization across multiple equipment types minimizes spare parts inventory

-

Multiple configurations: Single, Dual, Pusher, and Metal Bellows

-

Ideal for high cycling and stop-start systems

Standardize your operations with industry-leading reliability. The Flowserve ISC2 Series is the smart choice for engineers and operators seeking dependable mechanical sealing solutions across general and mission-critical applications. Contact us today for product recommendations, API compliance consultation or to request a datasheet, our experts are ready to assist your sealing system needs.

Flowserve Chemiepac 970

Flowserve Chemiepac 970

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve Chemiepac 970 is a nonmetallic PTFE bellows mechanical seal engineered for long-lasting performance in corrosive liquid applications. Designed to withstand aggressive acids, alkalis, solvents and volatile organic compounds, it is ideal for industries demanding high chemical resistance and process reliability. With its outside-mounted configuration, the Chemiepac 970 offers easy installation and reduced risk of shaft damage. The PTFE construction provides superior compatibility with a wide range of corrosive fluids, making it a preferred solution in chemical processing, pharmaceutical and waste treatment environments. |

Chemiepac 970 Applications and Industries

Industries:

-

Acid Transfer

-

Chlor-Alkali and Caustics

-

Auxiliary Chemical Systems

-

Solvent and VOC Handling

-

Slurry Processing

-

Pharmaceuticals

-

Polymer Production

-

Waste Treatment

Key Features and Benefits

-

PTFE bellows construction for extreme corrosion resistance

-

Outside-mounted design for easy installation and serviceability

-

Ideal for hazardous, toxic, or chemically aggressive fluids

-

Nonmetallic build prevents contamination and corrosion

-

Compatible with a wide range of chemical process pumps

Flowserve Seals – Products and Services Catalogue

Need a seal that can withstand the most corrosive fluids? The Flowserve Chemiepac 970 is the proven PTFE bellows seal trusted across industries for acid, solvent and caustic service applications. Get in touch with us today to request specifications, compatibility checks or pricing for your critical sealing application.

Flowserve BXLS Seal – DIN-Style Metal Bellows Seal

Flowserve BXLS Seal – DIN-Style Metal Bellows Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve BXLS is a DIN version of the proven BX Series mechanical seal, featuring a balanced, rotating welded metal bellows design ideal for both corrosive and non-corrosive services. Built to handle fluids with a specific gravity of 0.45 or higher, the BXLS provides robust sealing performance under extreme temperatures and pressures. Compliant with API 682 Type B specifications, the BXLS is widely used in refineries, petrochemical plants, and critical service pumps. Its versatility and durability make it suitable for aggressive hydrocarbons, acids and slurries. Available in single, double and tandem configurations, the BXLS supports a wide range of operating environments and pump types |

BXLS Seal Applications and Industries

Industries:

-

Crude Oil Handling & Treatment

-

Hydrocracking

-

Alkylation

-

Catalytic Cracking

-

Delayed Coking

-

SAGD (Steam Assisted Gravity Drainage)

-

Heavy Oil Upgrading

-

Acid and Solvent Transfer

-

Water Injection & Treatment

-

Waste Processing

-

Polymers and VOC Handling

-

Utilities, Auxiliary, and Tank Farms

-

Pharmaceuticals

-

Slurry Processing

Standards Compliance:

-

DIN24960

-

API 682 Type B

Key Features and Benefits

-

Rotating welded metal bellows for high reliability in harsh media

-

Balanced seal design for stability under high-pressure service

-

DIN24960 dimensions for global pump compatibility

-

Fully compliant with API 682 Type B for refinery-grade performance

-

Available in single, double, and tandem seal arrangements

-

Ideal for aggressive, high-SG, or thermally dynamic processes

BX Seal Installation Instruction

Flowserve Seals – Products and Services Catalog – English

Need a DIN-compliant solution for refinery-grade sealing? The Flowserve BXLS Seal is engineered for performance, compliance and flexibility in corrosive, abrasive or high-temperature applications. Contact us today to request specifications, compatibility consultation or pricing for your process pumps and rotating equipment.

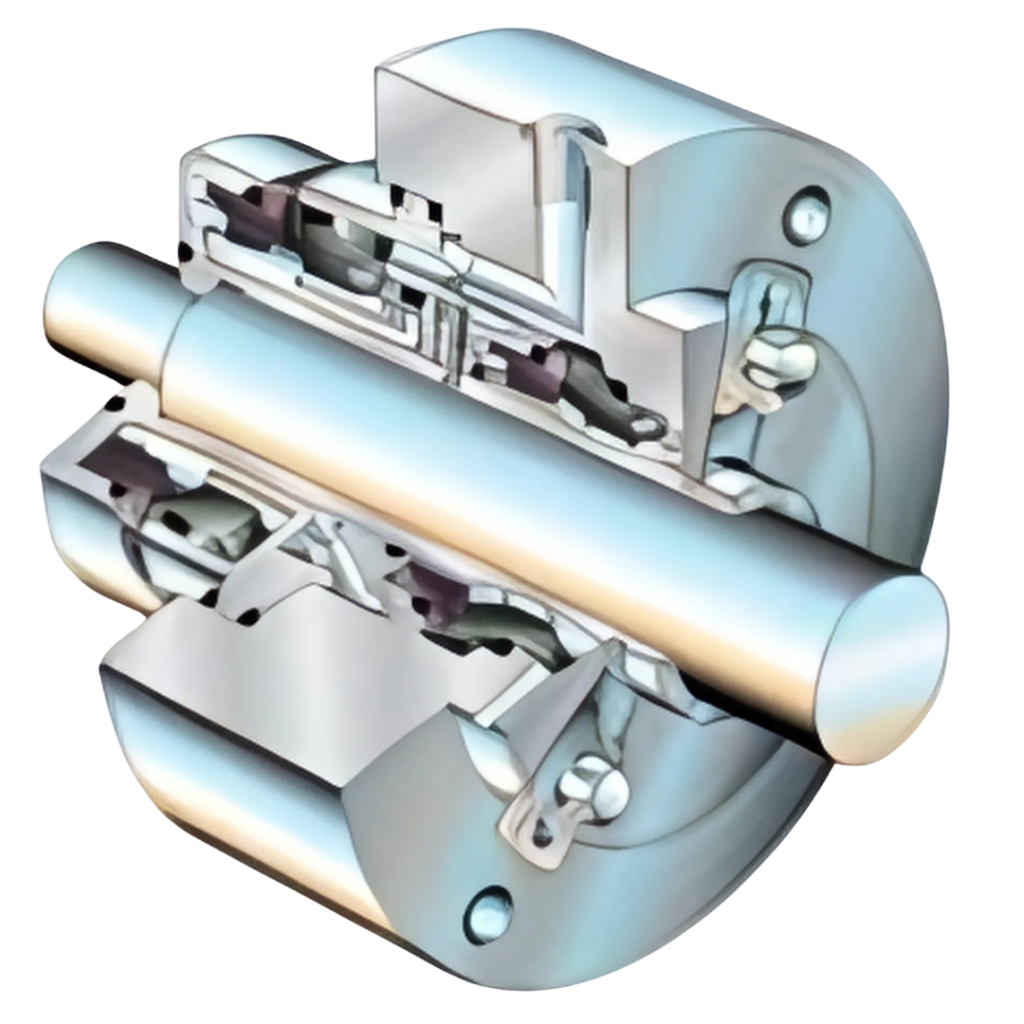

Flowserve ISC2BB – Dual Bellows Cartridge Seal

Flowserve ISC2BB – Dual Bellows Cartridge Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve ISC2BB is a dual bellows mechanical seal in a modular cartridge design, engineered for chemical, wastewater, slurry and high-demand industrial applications. Designed for flexibility and ease of service, the ISC2BB features interchangeable parts with other ISC seal versions, reducing inventory and simplifying maintenance. With its tandem configuration and double-balanced design, the ISC2BB is suitable for both pressurized and unpressurized operations, enabling broader system compatibility. The bellows module, constructed from Alloy C-276, offers excellent chemical resistance in corrosive media environments. A high-efficiency pumping ring promotes superior barrier fluid circulation, keeping the seal chamber cooler and improving reliability over long service cycles. |

Applications and Industries

Industries Served:

-

Chemical Processing

-

Wastewater Collection and Treatment

-

Pulp and Paper

-

Food and Beverage

-

Pharmaceuticals

-

Agriculture

-

HVACI and Boiler Feed

-

Desalination and Water Supply

-

Solvent Handling

-

Slurry and Acid Transfer

-

Polymers and Coatings

-

Automotive and Aerospace

-

OEM and General Industry

-

Snowmaking, Cryogenic, and Cooling Systems

Standards:

-

ASME (ANSI)

-

ISO

Key Features and Benefits

-

-

Dual bellows seal in tandem, double-balanced configuration

-

Modular cartridge design with part interchangeability across ISC models

-

Alloy C-276 bellows for outstanding corrosion resistance

-

High-efficiency pumping ring for improved cooling and longer seal life

-

Compatible with ANSI standard bore, ANSI enlarged bore, and DIN standard pumps

-

Available in multiple materials to match a wide range of chemical and slurry services

-

Built for long-term reliability in harsh and variable operating conditions

-

ISC Dual Rotating Bellows Seal Repair

Engineered for performance, built for reliability. The Flowserve ISC2BB dual bellows cartridge seal offers unmatched modular flexibility, chemical compatibility and cooling efficiency, making it the ideal solution for challenging chemical and wastewater environments. Contact our team today for technical support, material compatibility checks or a quote tailored to your pump configuration.

Flowserve BXHHS Seal – High-Temperature Alloy 718 Metal Bellows Seal

Flowserve BXHHS Seal – High-Temperature Alloy 718 Metal Bellows Seal

The Flowserve BXHHS is a premium high-temperature mechanical seal designed for extreme petrochemical applications, including hydrocracking, hydrotreating, alkylation and delayed coking. Built with Alloy 718 welded metal bellows, the BXHHS offers superior resistance to corrosion, thermal distortion and mechanical fatigue, making it ideal for critical refinery operations.

This balanced, rotating seal features a self-cleaning bellows configuration to minimize fouling, especially in applications with solids or heavy hydrocarbons. Its low-stress bellows geometry and shrink-fit stationary face design ensure low leakage, minimal face wear and long-term seal performance even under cycling or transient conditions.

BXHHS Seal Applications and Industries

Industries:

-

Heavy Oil and Upgrading

-

SAGD (Steam Assisted Gravity Drainage)

-

Hydrotreating

-

Hydrocracking

-

Catalytic Cracking

-

Delayed Coking

-

Crude Oil Handling and Treatment

-

Alkylation

-

Distillation

Ideal For:

-

High-pressure, high-temperature pumps in refinery environments

-

Systems with aggressive media, solids and rapid thermal changes

-

Facilities requiring full API 682 Type C compliance

Key Features and Benefits

-

Alloy 718 metal bellows provide high strength and resistance to stress corrosion cracking

-

Balanced rotating design improves seal stability at high speed and temperature

-

Shrink-fit stationary face minimizes distortion, enabling tighter sealing

-

Low leakage performance over a wide range of thermal and pressure cycles

-

Self-cleaning bellows prevent fouling in heavy-duty and slurry-like environments

-

Meets API 682 Type C specification for hydrocarbon processing pump.

High Temperature Metal Bellows Seal Installation Instructions

Need a mechanical seal for the most extreme refinery conditions? The Flowserve BXHHS offers robust metal bellows technology, API 682 Type C compliance, and exceptional sealing performance for high-temperature, high-pressure hydrocarbon services. Contact us today to request datasheets, engineering support or pricing, our team is ready to help with sizing and compatibility for your toughest sealing challenges.

Flowserve CBR Seal

Flowserve CBR Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve CBR is a general-purpose single bellows mechanical seal designed for a wide range of standard industrial applications. Its rotating metal bellows design eliminates shaft packing hang-up and fretting, a common cause of premature failure in traditional seals. With Centroid Loaded Face Attachment, the CBR reduces seal face distortion due to thermal expansion, extending operational life and improving performance stability. The seal ring is easily replaceable, making the CBR a cost-effective and low-maintenance choice for pumps in diverse industries, from chemicals to wastewater and OEM systems |

CBR Seal Applications and Industries

Industries Served:

-

Agriculture

-

Chemical & Liquor

-

Pharmaceuticals

-

Water Treatment & Desalination

-

Cryogenic & Snowmaking

-

Polymers & Coatings

-

OEM and Construction

-

Automotive and Aerospace

-

Fire Protection Systems

-

Electronics and Plating

-

Wastewater and Dewatering

-

Paper Stock & Digester Systems

-

HVACI and Boiler Feed

-

Bleach & Acid Transfer

-

Flood Control and Ground Water Development

Key Features and Benefits

-

Rotating metal bellows eliminates shaft fretting and packing hang-up

-

Centroid Loaded Face Attachment prevents distortion and enhances seal face alignment

-

Seal ring is easily replaceable, reducing downtime and maintenance cost

-

Compatible with a wide range of general-purpose pumps

-

Ideal for non-extreme conditions with chemical, slurry, water, or auxiliary fluids

-

Robust and economical for OEMs and plant-wide standardization

Looking for a reliable and economical seal for standard pump applications? The Flowserve CBR offers simplicity, durability and easy maintenance, making it an ideal choice for general-purpose chemical, water and industrial systems. Contact us now to request the datasheet, check compatibility or receive a quote tailored to your application.

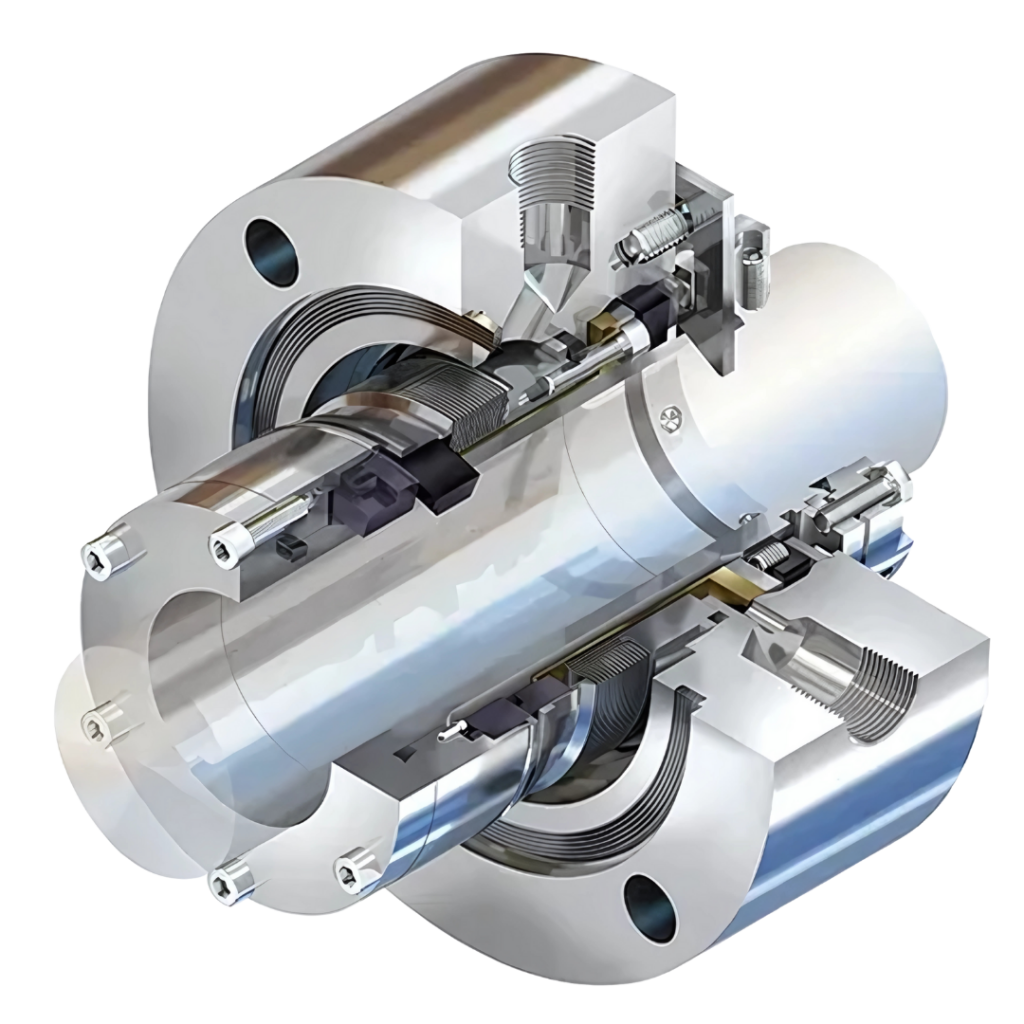

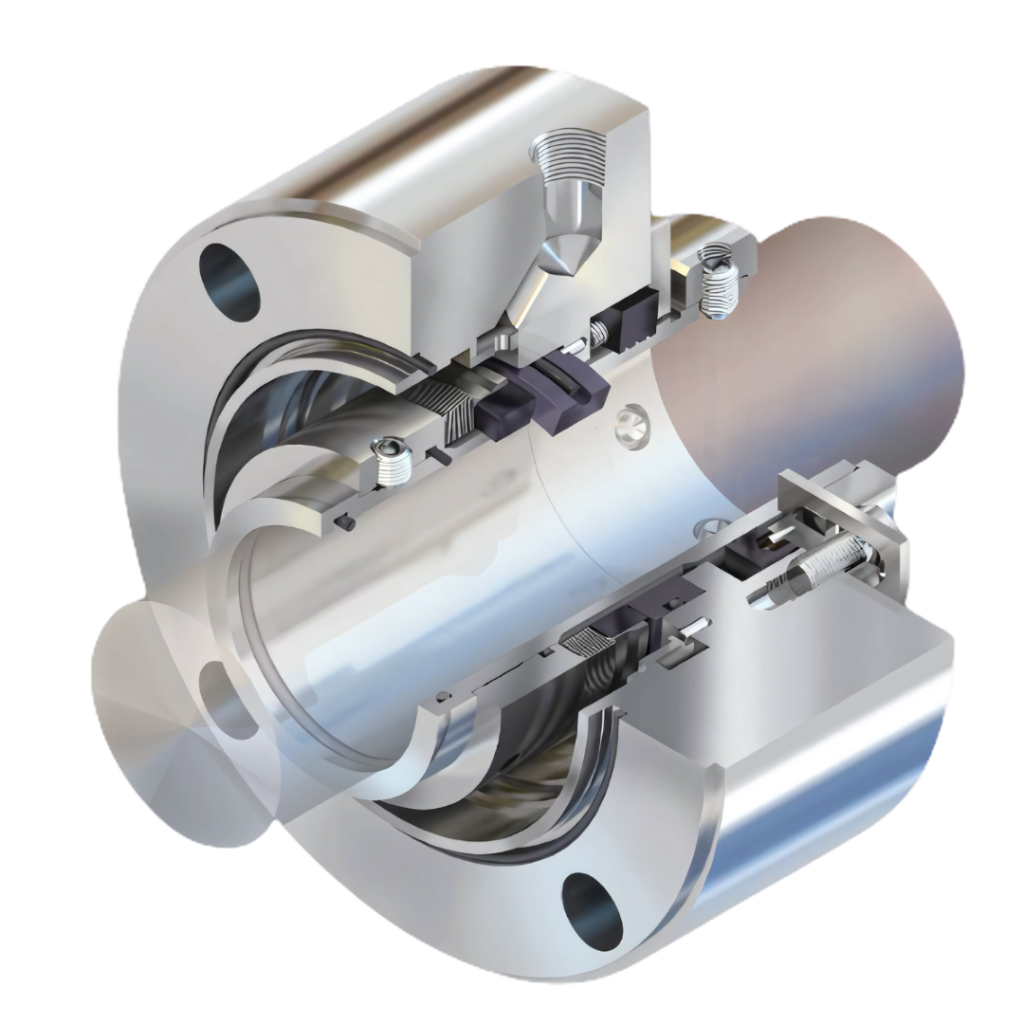

BX Metal Bellow Seal API682

BX Metal Bellow Seal API682

Flowserve’s BX Series API 682 Type B is a family of balanced metal bellows seals available in single and dual seal configurations. BX Series seals provide exceptional reliability in corrosive and non-corrosive fluids, especially fluids that crystalize or coke in atmospheric conditions. The BX Metal Bellow Seals is fully compliant with API 682 Type B requirements.

Balanced, rotating welded metal bellows seal for corrosive and non-corrosive services with specific gravity of .45 and higher. Fully complies with API 682 type B specifications for refinery and petrochemical applications. The BX seal is available in single, double, and tandem seal configurations.

Metal Bellow Seal Specification

Standards:

- API682

Features & Benefits

- 0.20 mm (0.008 inch) thick standard welded bellows provides maximum resistance to corrosion, shaft vibrations, and centrifugal forces

- Rotating bellows acts to clear convolutions and prevent accumulation of debris.

- Absence of springs and dynamic elastomers reduces clogging vulnerabilities.

- Circulating device integrated into the dual seal cartridge circulates barrier fluid to keep the seal faces cool. A circulating device is also available on single seals for fluids over 75°c (167°F)

- Available multi-port flush distributes flush fluid evenly around the seal faces for uniform cooling.

- Part interchangeability between single and dual seal arrangements minimizes inventory requirements and maximizes design flexibility.

Corrosive and Non-Corrosive Fluids Operating Parameters

| Pressure | Up to 28 bar (400 psi)

*Higher pressures available for selected sizes. |

| Temperature | -40 – 204°C (-40 to 400°F) |

| Specific Gravity | 0.45 and higher |

| Surface Speed | Up to m/s (75 fps) |

| Shaft Sizes | 12.3 to 152.4 mm (0.483 to 6.000 inch) |

Industrial Applications

- Polymers

- Catalytic Cracking

- Pharmaceuticals

- Crude Handling & Treatment

- Logistics & Tank Farm

- Delayed Coking

- Hydrotreating

- Hydrocracking

- Heavy Oil and Upgrading

- Water Injection

- Water Handling and Treatment

- Waste Processing

- Volatile Organic Compounds

- Utilities

- Solvents

- Acid Transfer

- Slurry Processing

- Alkylation

- Distillation

- Auxiliary

- SAGD

- Caustic

- Chlor-Alkali

Specialized Design for Specific Applications

| BXQ | High balance low emission hydrocarbon design for specific gravities down to 0.45 with multi-port flush. |

| BXB | Inner bellows designed for ID pressurization with barrier fluid. Standard API 682 Type B Arrangement 3 pressurized dual seal. |

| BXLS | Designed for international standard DIN EN 12 756 L1k for use in DIN pumps. |

| BXR | Stationary bellows design capable of speeds up to 40 m/s. |

Flowserve GTS Wavy Face Mechanical Seal

Flowserve GTS Wavy Face Mechanical Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve GTS is a non-contacting, single wavy face mechanical seal engineered specifically for steam turbine systems handling hot condensate, water and steam-water mixtures. Available in both integral and detachable designs, the GTS is compatible with a wide range of turbine styles and configurations. Utilizing thin film wavy face technology, the GTS provides stable, low-drag sealing performance with bi-directional capability, reducing installation error and increasing seal interchangeability. Its non-clogging face design enables fast recovery from upset conditions and minimizes operational risk in dynamic steam environments. Whether used in boiler circulation systems, condensate recovery or crude oil processing, the GTS is a robust sealing solution for demanding turbine applications. |

GTS Wavy Face Mechanical Seal Applications and Industries

Industries:

-

Steam and Condensate Systems

-

Boiler Feedwater and Circulation

-

Crude Handling and Pipeline

-

Alkylation

-

Hydrocracking and Hydrotreating

-

Distillation and Delayed Coking

-

Heavy Oil and Upgrading

-

Catalytic Cracking

-

SAGD (Steam Assisted Gravity Drainage)

-

Utilities and Cooling Systems

-

Logistics and Tank Farms

-

Water Handling, Injection, and Treatment

-

Products Pipelines

-

General Power and Miscellaneous Services

Key Features and Benefits

-

Wavy face design enables non-contacting seal operation, reducing energy loss and wear

-

Handles hot condensate, water and steam-water mixtures with high reliability

-

Bi-directional face configuration simplifies installation and minimizes handling errors

-

Non-clogging wavy face technology allows quick recovery from upset conditions

-

Available as internally or externally mounted to suit various turbine designs

-

Ideal for steam turbines in chemical, power, refining and energy sectors

Optimized for reliability in steam turbine applications. The Flowserve GTS seal is your solution for high-efficiency, non-contacting turbine sealing, offering long service life even in hot condensate and mixed-phase environments. Contact us today to request technical datasheets, discuss system compatibility or receive a quote tailored to your turbine sealing needs.

Flowserve X-100 Seal Single Bellows Cartridge Seal

Flowserve X-100 Seal Single Bellows Cartridge Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve X-100 is a single bellows mechanical seal in a cartridge design, developed for a broad range of chemical, slurry, water and utility applications. Its rotating bellows module is engineered to resist clogging, making it suitable for media with solids, scaling tendencies or variable flow conditions. Constructed using various high-alloy metallurgies including Alloy C-276, the X-100 provides exceptional chemical compatibility across aggressive process environments. The seal also shares the same gland as the Flowserve X-200 dual seal, making it ideal for sites looking to streamline parts inventory and simplify maintenance. An optional throttle bushing is available for added safety in hazardous or pressurized systems. Compatible with all ANSI standard bore, ANSI enlarged bore and DIN standard chemical pumps, the X-100 is a trusted and versatile sealing solution. |

X-100 Seal Applications and Industries

Industries Served:

-

Desalination

-

Acid Transfer

-

Slurry Transfer and Processing

-

Agriculture and Irrigation

-

Electronics and Cryogenics

-

Construction and OEM Systems

-

Cooling Water (Metals)

-

Paper Stock and Coatings

-

Bleach and Chemical Liquor Handling

-

Automotive and Aircraft Systems

-

Boiler Feed and HVACI

-

Food Processing

-

Pharmaceuticals

-

Water Treatment and Supply

-

Plating, Galvanizing, and VOC Handling

-

Wastewater and Dewatering

-

Fire Protection, Flood Control, and Auxiliary Services

Key Features and Benefits

-

Single welded metal bellows design for durability and long seal life

-

Cartridge configuration simplifies installation and alignment

-

Rotating bellows module resists clogging, ideal for solids-laden or scaling fluids

-

High alloy metallurgy options, including Alloy C-276, for excellent chemical resistance

-

Interchangeable gland with Flowserve X-200 dual seal for simplified stocking

-

Optional throttle bushing enhances safety in hazardous applications

-

Fits ANSI and DIN standard chemical pumps

X-100 Seal Installation Instructions

Need a simple, reliable solution for your chemical or utility pump? The Flowserve X-100 delivers proven performance in a compact cartridge design, ideal for high-compatibility, low-maintenance sealing across a wide range of process conditions. Contact us today to request a datasheet, discuss compatibility or receive a quote based on your pump model and media.

Flowserve Allpac N – DIN 24960 Form C Balanced Mechanical Seal

Flowserve Allpac N – DIN 24960 Form C Balanced Mechanical Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve Allpac N is a wavy spring mechanical seal cartridge engineered for DIN 24960 Form C compatibility. Available in single, double, or tandem configurations, the Allpac N is designed specifically for challenging services such as slurry transfer, acid handling, and chemical processing. Each seal pair utilizes two 100% identical seal faces, ensuring long-term sealing symmetry and wear balance. In double seal configuration, the inboard seal is reverse pressurized, greatly enhancing resistance to clogging and ensuring reliable operation in slurry-laden or viscous environments. The seal is available only in four standard DIN sizes, making it a precise fit for applications using DIN Form C metric equipment. |

Applications and Industries

Industries Served:

-

Slurry Transfer & Processing

-

Primary and Mineral Processing

-

Polymers and Pharmaceuticals

-

Acid Transfer and Leaching

-

Caustic and Chlor-Alkali Systems

-

Solvent and VOC Handling

-

Dewatering and Water Supply

-

Auxiliary and Utility Systems

-

Waste Processing

Key Features and Benefits

-

Compliant with DIN 24960 Form C specifications

-

Available in single, tandem, or double balanced cartridge configurations

-

Wavy spring design offers robust seal face loading in variable operating conditions

-

100% identical seal face pairs improve performance and wear distribution

-

Reverse pressurized inboard seal (in double configuration) resists clogging in slurry applications

-

Designed for metric DIN Form C pumps – available in four standard sizes

-

Easy installation and maintenance in cartridge format

General Installation and Maintenance Instructions

Need a reliable DIN 24960 Form C seal for slurry or chemical applications? The Flowserve Allpac N delivers durable, clog-resistant sealing in single, tandem, or double balanced configurations, perfect for process-critical operations involving slurries, acids or VOCs. Contact us today to request sizing info, datasheets or a quotation tailored to your equipment and media.

Flowserve BXRH – Stationary Alloy 718 Bellows Seal

Flowserve BXRH – Stationary Alloy 718 Bellows Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve BXRH is a stationary, balanced metal bellows mechanical seal constructed from Alloy 718, purpose-built for extreme high-temperature petrochemical and refining services. Designed to meet API 682 Type C specifications, this seal ensures optimal performance in volatile, high-pressure and high-temperature environments. Its stationary bellows configuration provides superior stability in applications where shaft movement or thermal cycling may compromise rotating designs. With excellent resistance to corrosion, thermal distortion and mechanical fatigue, the BXRH is ideal for critical rotating equipment used in upstream and downstream refinery operations. |

BXRH Applications and Industries

Industries Served:

-

Alkylation

-

Crude Oil Handling & Treatment

-

Catalytic Cracking

-

Delayed Coking

-

Distillation Units

-

Hydrocracking

-

Hydrotreating

-

SAGD (Steam Assisted Gravity Drainage)

-

Heavy Oil Upgrading

Ideal For:

-

High-temperature rotating equipment

-

API 682 Type C process pumps

-

Seal installations with thermal or pressure cycling

Key Features and Benefits

-

Stationary welded Alloy 718 bellows for enhanced reliability in extreme environments

-

API 682 Type C compliant – trusted performance for refinery and petrochemical services

-

Balanced seal design ensures pressure stability and longer service life

-

Ideal for thermal shock conditions and shaft movement-sensitive applications

-

Designed for high-pressure, high-temperature, and aggressive hydrocarbon media

Operating in high-temperature, corrosive refinery conditions? The Flowserve BXRH offers unmatched reliability and thermal resilience through its stationary Alloy 718 bellows design, making it the seal of choice for API 682-compliant systems. Contact us today to request technical datasheets, confirm compatibility with your pump model or receive a tailored quotation.

Flowserve X-200 – Dual Welded Bellows Cartridge Seal

Flowserve X-200 – Dual Welded Bellows Cartridge Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve X-200 is a dual welded metal bellows cartridge seal engineered for high-performance sealing in chemical, slurry, utility, and water treatment applications. Designed for flexibility and reliability, it operates in both pressurized and unpressurized environments with equal efficiency. Its rotating bellows modules are clog-resistant and constructed from high alloy leaflet metallurgies, including Alloy C-276, offering excellent chemical compatibility for aggressive media. A bi-directional flow inducer built into the gland promotes internal fluid circulation, which helps maintain cooler seal temperatures and extends seal life. The X-200 is compatible with all ANSI standard bore, ANSI enlarged bore, and DIN standard chemical pumps, making it ideal for facilities standardizing across pump types. |

Flowserve X-200 Applications and Industries

Industries Served:

-

Water Treatment & Desalination

-

Acid & Slurry Transfer

-

Fire Protection Systems

-

Flood Control & HVACI

-

Pharmaceuticals & Food Processing

-

Chemical and Liquor Processing

-

Solvent, VOC, and Caustic Handling

-

OEM and General Industry

-

Electronics, Plating & Coatings

-

Automotive and Aerospace

-

Wastewater and Dewatering

-

Agriculture and Irrigation

-

Snowmaking and Cryogenic Systems

Key Features and Benefits

-

Dual rotating welded metal bellows construction for high reliability

-

Cartridge design simplifies installation and reduces alignment error

-

Clog-resistant bellows ideal for slurry, scale, or viscous fluids

-

Alloy C-276 metallurgy for compatibility with aggressive chemicals

-

Operates in pressurized or unpressurized conditions

-

Bi-directional flow inducer maintains optimal seal chamber temperature

-

Compatible with ANSI and DIN standard chemical process pumps

X-200 Seal Installation Instructions

Need a durable, clog-resistant seal for your toughest applications? The Flowserve X-200 is engineered for reliability in chemical, water, slurry and utility services, with dual bellows technology and built-in cooling flow for extended life and reduced downtime. Contact us today to request technical specifications, check pump compatibility or receive a quotation tailored to your system requirements.

Flowserve ISC1EX – Modular Elastomer Bellows Cartridge Seal

Flowserve ISC1EX – Modular Elastomer Bellows Cartridge Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve ISC1EX is a single bellows mechanical seal featuring a modular cartridge design, tailored for general-purpose sealing applications across chemical, water and utility industries. Built on proven Pac-Seal elastomer bellows technology, this model delivers cost-effective reliability in a wide range of operating environments. The elastomer bellows module is available in multiple material options to ensure compatibility with different chemical and process media. Its modular design allows interchangeability with other ISC series parts, simplifying maintenance and inventory management. Suitable for use with ANSI standard bore, ANSI enlarged bore and DIN standard chemical pumps, the ISC1EX is designed for wide industry adoption. |

ISC1EX Applications and Industries

Industries Served:

-

Water Treatment and Supply

-

Chemical and Liquor Processing

-

Wastewater and Dewatering

-

Slurry Transfer and Processing

-

Food and Beverage

-

Pharmaceuticals

-

Desalination and Cryogenics

-

Coatings, Plating, and Galvanizing

-

Boiler Feed and HVACI

-

Acid, Solvent, and VOC Handling

-

Agriculture and Irrigation

-

Automotive and Aerospace

-

OEM and Construction

-

Fire Protection Systems

-

Flood Control and Snowmaking

Key Features and Benefits

-

Proven Pac-Seal elastomer bellows technology

-

Modular cartridge construction simplifies installation and servicing

-

Interchangeable parts with other ISC models to reduce inventory complexity

-

Available in multiple elastomer materials for broader chemical compatibility

-

Compatible with ANSI and DIN standard process pumps

-

Reliable and economical for general-purpose pump sealing

Looking for a versatile and economical cartridge seal solution? The Flowserve ISC1EX combines Pac-Seal elastomer technology with a modular cartridge design for easy maintenance, broad chemical compatibility and seamless integration with ANSI and DIN standard pumps. Contact us today to request technical specs, compatibility checks or a quotation tailored to your application.

Flowserve BXR – Stationary Welded Metal Bellows Seal

Flowserve BXR – Stationary Welded Metal Bellows Seal

| Brand | Flowserve |

|---|---|

| Description |

The Flowserve BXR is a balanced, stationary metal bellows mechanical seal built for general service in chemical and petrochemical processing. Its stationary bellows configuration makes it less sensitive to misalignment and off-squareness, offering greater sealing stability in rotating equipment. This design also enables the seal to handle higher shaft speeds, making the BXR a solid choice for demanding services like hydrocracking, SAGD, solvent recovery and waste treatment. Compliant with API 682, the BXR is engineered for long-term reliability in applications with aggressive fluids, high pressures and variable thermal conditions. |

Flowserve BXR Applications and Industries

Industries Served:

-

Petrochemical and Refining

-

SAGD (Steam Assisted Gravity Drainage)

-

Distillation and Hydrotreating

-

Heavy Oil Upgrading

-

Solvent Recovery Systems

-

Slurry Processing

-

VOC and Acid Transfer

-

Utilities and Water Handling

-

Waste Processing and Tank Farms

-

Delayed Coking

-

Catalytic Cracking

-

Pharmaceuticals and Polymers

-

Chlor-Alkali and Auxiliary Services

-

Logistics and Crude Oil Handling

Key Features and Benefits

-

Stationary bellows design improves tolerance to misalignment and dynamic runout

-

Balanced welded construction supports higher pressure and thermal loads

-

Handles high-speed shaft conditions in rotating equipment

-

Ideal for chemically aggressive and thermally variable environments

-

API 682 compliance ensures industry-standard reliability and interchangeability

-

Built for long service life in general and critical sealing services

Flowserve Seals – Products and Services Catalogue- English

Need a high-speed, misalignment-tolerant seal for refinery or chemical service? The Flowserve BXR offers robust sealing performance with stationary metal bellows construction, delivering greater reliability in tough conditions and API 682-compliant quality. Contact us today to request datasheets, material compatibility information or a tailored quotation for your pump configuration.