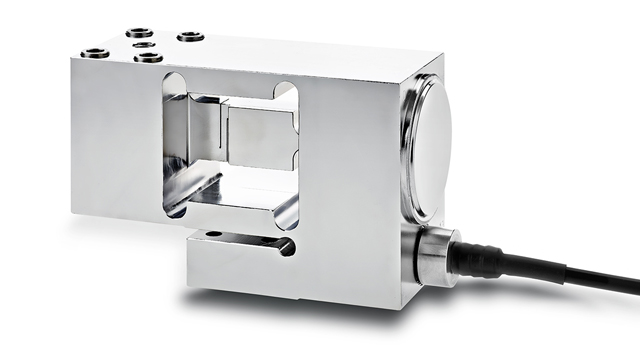

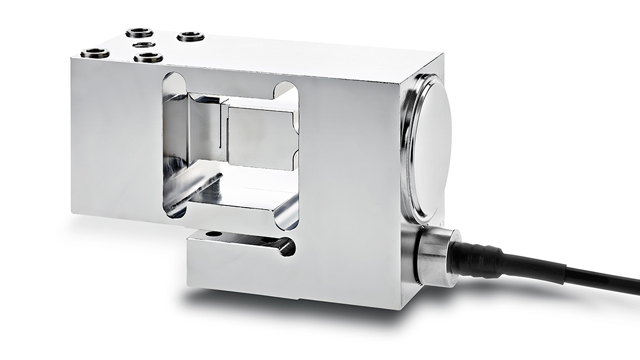

Alfa Laval Single Point Load Cells

Alfa Laval Single Point Load Cells

Alfa Laval Single Point Load Cells

Ideal for weighing on small hoppers and vessels, scales or conveyor belts from 5 to 150 kg.

Related Industries:

Biotech and Pharmaceuticals, Food and beverage

Robust and hygienic solution

The Alfa Laval weighing system UltraPure is a comprehensive solution for hygienic process weighing and measurement of liquid level, mix ratios, dosage or batching. With its patented technology, mounting kits are unnecessary, allowing for quick and easy set-up and a faster, more cost-effective installation process. Its complete laser-welded construction makes it ideal for production environments that are hosed down daily.

Quick and easy set-up

The pre-calibration of the Alfa Laval load cells eliminates the need for on site calibration in many applications. Mechanical protection devices are not necessary when installing Alfa Laval digital load cells, reducing both cost and maintenance while ensuring a hygienic installation.

High weighing accuracy

Weighing accuracy depends largely on the selection of a top quality load cell for your weighing system. Alfa Laval provides two standard accuracy ranges 0.05% and 0.025% covering a measurement range from 0 to 150 kg.

Single Point Load Cells Benefits

- Robust and hygienic solution

- Quick and easy set-up

- High weighing accuracy

Operating principle

The Alfa Laval shockproof digital load cells are based on a patented capacitive measurement principle where a non contact capacitive sensor is mounted inside the load cell body. Each weighing system consists of several load cells, including load cell modules, an electronic output module (analogue or digital) and control modules for the load cells and cable. To ensure a robust and reliable connection between the tank and the load cells, Alfa Laval offers an additional range of tank legs that fit the load cells. When a load is applied, a portion of the load is transmitted to each load cell, which sends an electrical signal proportional to the load to the control module. The control module converts these signals to an accurate weight reading.

Reliable, low cost operation

Because the capacitive sensor is not in contact with the load cell body, the load cells are largely unaffected by overloads, side loads, shocks and welding voltages. This enables straightforward mechanical installation without the expense of complicated mounting kits or overload protection devices.

Plug and play installation

A standard RG 58 coaxial cable up to 50 meters in length is all that is required to install the weighing system. A patented Application Specific Integrated Circuit (ASIC) directly converts, compensates and calibrates the signal from the non contact capacitive sensor. Calibration of the digital load cells is independent of the load cell cable length.