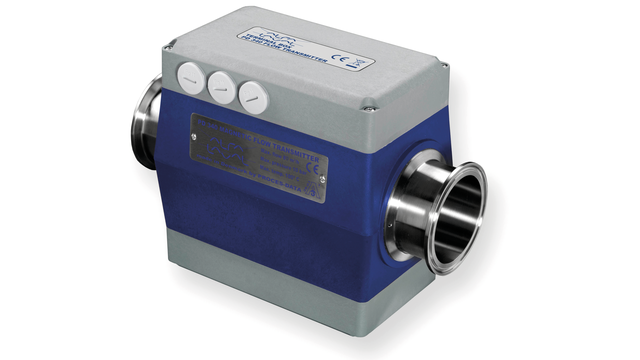

Alfa Laval Flow Transmitter

Alfa Laval Flow Transmitter

Alfa Laval flow transmitters are electromagnetic precision meters used to measure the volumetric flow rate of electrically conductive liquids. Hygienically designed, these are excellent choices for use in the dairy, food and biopharma industries.

Related Industries:

Food and beverage, Home and Personal care

High precision flow measurement

Alfa Laval flow transmitters are bi-directional electromagnetic precision meters used to provide accurate process flow measurement of electrically conductive liquids. They are especially suitable for installations where solid particles are present in the liquid. With no moving parts and no pressure drop, these flow transmitters provide high accuracy, excellent long-term stability and performance.

Durable hygienic flow transmitter design

Authorized to carry the 3-A symbol, Alfa Laval flow transmitters feature a sturdy waterproof design. Other hygienic features, such as the (PFA) Teflon coating on the interior of the metering tube and completely embedded, hermetically sealed electronics, contribute to long service life of these magnetic inductive flow transmitters.

Compact and easy to install

Designed for tight mounting positions, standard Alfa Laval flow transmitters are delivered with pre-set factory pulse output signals to facilitate installation. The standard output is a pulse signal (0 to 1000 Hz) with a resolution of either 0.01 or 0.1 liter/pulse. Analogue 4-20 mA output and advanced display-enabling features are available as options.

Terminals for electrical connection are marked with both number and function; all cables can be threaded through three PG-11 cable glands.

Operating principle

The Alfa Laval flow transmitter is a magnetic inductive flow transmitter that operates according to Faraday’s law of electromagnetic induction. It consists of a metering pipe and two magnetic coils. When a current is applied to the coils, a magnetic field is produced at right angles to the metering pipe.

The liquid to be measured flows through the metering pipe perpendicular to the magnetic field. It acts as a conductor and induces an electrical voltage. Two sensing electrodes mounted in the metering pipe measure this voltage. The voltage is proportional to the average flow velocity and therefore accurately reflects the volume of the liquid flowing through the tube.

Constructed to handle multiple liquids

The Alfa Laval flow transmitter uses a square measurement chamber. This design reduces the influence of viscosity, liquid type, and flow profiles, eliminating the need for recalibration when switching products (for example, from milk to water). The microprocessor controls the current generator to maintain a constant magnetic field while converting the measured voltage into a digital flow measurement.

Alfa Laval Flow Transmitter Application

The Alfa Laval Flow Transmitter is designed for hygienic and pharmaceutical production. It is suitable for measuring flow in Food, Beverage, Dairy, and Biopharm industries. Main features include:

- Independent of variations in flow profile, solids presence, and changes in product viscosity.

- Meets 3-A standards for hygienic applications.

- No internal pressure drop.

- Robust, compact design; temperature tolerant up to 115°C.

- Easy mounting even in challenging conditions.

- High accuracy and linearity.

- Pre set-up from the factory, ready for installation.

- Bidirectional measurement capability.

- No moving parts – minimal maintenance.

TECHNICAL DATA

Accuracy: ±0,02 % of FS (testbench) < ±0,2 % of FS (working conditions)

Repeatability: Max 0.5* accuracy

Media conductivity: Min 5 µS/cm

Measuring ranges

0 to 8 m³/h (2113 GPH), (connection: DN25)

0 to 20 m³/h (5284 GPH), (connection: DN38)

0 to 40 m³/h (10568 GPH), (connection: DN51)

0 to 80 m³/h (21136 GPH), (connection: DN63)

0 to 120 m³/h (31704 GPH), (connection: DN76)

0 to 200 m³/h (52840 GPH), (connection: DN102)

Resolution output signal

TE67A1XXXXXXXX: 0.01 liter/pulse

TE67A2XXXXXXXX: 0.01 liter/pulse

TE67A3XXXXXXXX: 0.10 liter/pulse

TE67A4XXXXXXXX: 0.10 liter/pulse

TE67A5XXXXXXXX: 0.10 liter/pulse

TE67A6XXXXXXXX: 0.10 liter/pulse

Protection class: IP67

Max media pressure: 10 bar

Electrical data

Power supply: 24 V AC/DC (0.25A)

Electrical connection: Pg11 cable gland

Response time

Pulse output: 0.2 sec.

4-20 mA: 1 sec.

Output

Pulse output: (0 to 1000 Hz), 4-20 mA (option), Profibus DP (option)

PHYSICAL DATA

Materials

Wetted parts: AISI 316 and PFA

Housing: Noryl

Operating temperature (Wetted parts): -30 to 115°C

Electronics range: -10 to 50°C

Weight

Flow transmitter: 5 kg (TE67A6: 10 kg)

Process connections

TE67A1XXXXXXXX: clamp DN25

TE67A2XXXXXXXX: clamp DN38

TE67A3XXXXXXXX: clamp DN51

TE67A4XXXXXXXX: clamp DN63

TE67A5XXXXXXXX: clamp DN76

TE67A6XXXXXXXX: clamp DN102

Certificates

- Calibration certificate (option)

- 3.1 certificate (option)

Electrical data

The transmitter is pre-setup from the factory with integrated automatic zero point adjustment. Optional features include a display for temperature compensation (via external pt100 sensor), PI regulator, and low-flow linearization.

Standard range

The standard version is delivered pre-setup for quick installation. The output signal is a pulse (0 to 1000 Hz) with a resolution of either 0.01 or 0.1 liter/pulse, with options for analogue 4-20 mA or Profibus DP. The metering tube is PFA-coated and features clamp connections. Electronics are embedded and hermetically sealed, ensuring waterproof protection (IP67) with cable access via 3 PG-11 cable glands.

Working principle

The transmitter uses a metering pipe and two magnetic coils. A conductive liquid flowing through the pipe induces a voltage across two electrodes, which is then converted into a volumetric flow measurement by the microprocessor.