Top Features of Alfa Laval Gasket Plate-and-Frame Heat Exchangers You Should Know

Alfa Laval Gasket Plate and Frame Heat Exchangers come in various types and designs such as gasket plate, brazed plate and fusion-bonded plate, each tailored to meet specific process requirements and industry applications. Among these, this article will focus on Gasket Plate and Frame Heat Exchangers (GPHEs). In Southeast Asia, GPHEs have become widely adopted and find usage in industries like HVAC, dairy and food processing, chemical processing, oil production, pharmaceuticals, biotech and power generation for applications including cooling, heat recovery, temperature control and fluid handling.

Why are these Gasket Plate and Frame Heat Exchangers features important?

A common misconception in the industry is that all industrial gasketed plate heat exchangers are the same, regardless of the brand. However, quite a few design features can have a significant impact on the performance of your operation. The following components offer major benefits when combined, including:

- Lower installation, maintenance and spare parts costs

- Reduced energy consumption

- Shorter downtime and faster servicing

- Higher production output

- Better safety for maintenance personnel

What is a Gasket Plate and Frame Heat Exchangers?

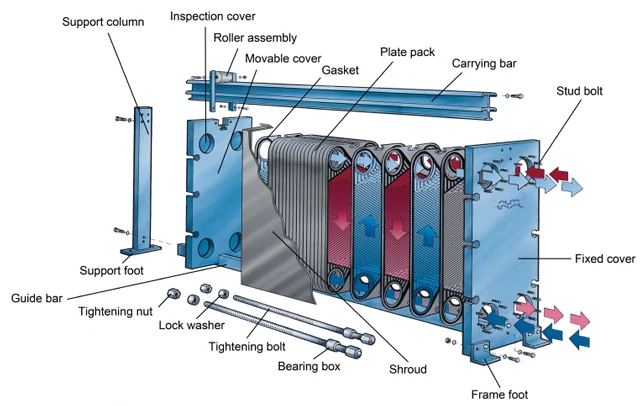

A plate heat exchanger gasket is built from corrugated metal plates sealed with rubber gaskets to form alternating flow channels. Manufacturers may replace some gaskets with laser-welded seals for applications involving aggressive fluids. The plate pack is assembled between a fixed frame plate and a movable pressure plate, compressed by tightening bolts and supported by a guide bar system fixed to a support column. Each GPHE is customised based on application-specific requirements such as pressure, temperature and heat duty, ensuring efficient performance while minimising material use.

Plate Heat Exchanger Gasket Frame Components Materials

Frame & Pressure Plate: Typically made from carbon steel, with variations in recycled content depending on the supplier.

Other Options: Commonly constructed from aluminium, chromium or stainless steel, depending on the environment and load requirements.

Plate Heat Exchanger Gasketed Construction and Plate Materials

Plate: Stainless steel alloys 304 and 316, used in 80–85% of installations. The degree of recycled material in stainless steel alloys 304 and 316 typically ranges between 60–90%, supporting sustainable manufacturing goals.

Other Options: Titanium, nickel, and high-performance nickel-based alloys are available for corrosive or high-temperature duties.

Key Features of Alfa Laval Gasket Plate Heat Exchangers That Make a Difference

Source image: Alfa Laval

For Reliability

For Serviceability

With the right features, Gasket Plate and Frame Heat Exchangers offer a highly efficient and cost-effective solution, ideal for various industries. Whether you’re operating a food processing plant or installing an HVAC system, our team is here to help. Get in touch with our engineers today for expert guidance on selecting the right heat exchangers for your application.

Source:

Gasketed plate heat exchangers | Alfa Laval

GPHE vs shell-and-tube | Alfa Laval

FAQ

1.Why choose Alfa Laval Gasket Plate and Frame Heat Exchangers over other brands?

Unlike traditional shell-and-tube exchangers, Alfa Laval Gasket Plate and Frame Heat Exchangers deliver exceptional heat transfer performance within a significantly smaller footprint. The units also have a flexible design and are easy to service and maintain.

Gasket Plate and Frame Heat Exchangers benefits:

- High thermal efficiency with actual counter-current flow 80-90% less hold-up volume

- Low capital investment, reduced installation costs, limited maintenance and operating costs

- Maximum reliability with minimal fouling and wear for long-term reliability

- Environmentally responsible, minimum energy consumption

- Easy to expand capacity, add or remove plates on the existing frame

2.How do I know which Alfa Laval heat exchanger model is right for my application?

Selecting the right hygienic plate heat exchanger model can be challenging, but we’re here to help. Speak with our engineers to find the best fit for your industrial needs.

3.When should a Gasket Plate and Frame Heat Exchangers be cleaned?

Regular cleaning of your industrial gasketed plate heat exchanger is crucial to maintaining optimal thermal efficiency, preventing fouling and avoiding unplanned downtime. Scheduled cleaning proactively before any signs of performance loss, pressure drop or product contamination occur. Contact our certified field service engineers to evaluate your system and recommend the ideal cleaning method and frequency based on your operating conditions.