HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

| Brand: | IDP |

|---|---|

| Description: |

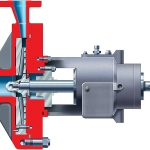

Fully compliant with ISO 13709 / API 610 (OH2), the Flowserve HPXM is a horizontal overhung process pump specifically engineered for low-flow, high-head applications. Designed to operate reliably under extreme conditions, the HPXM is ideal for critical services such as chemical injection, boiler feed, and high-pressure process systems in the oil, gas, and chemical industries. Its heavy-duty construction, optimized hydraulics, and compact OH2 footprint ensure stable performance, excellent efficiency, and long service life. |

Fully compliant with ISO 13709/API 610 (OH2), latest edition, the HPXM is specifically designed for low flow, high head process applications.

HPXM Applications

Solvents, Residuum and Heavy Oil Upgrading, Volatile Organic Compounds, Digester, Water Supply and Treatment (oil and gas), Distillation (oil and gas), Water and CO2 Injection, Drilling and Production, FPSO, Gas Treating and Sulfur Recovery, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Acid Transfer, Hydrocracking, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, LNG, Caustic and Chlor-alkali, Leaching Acid, Chemical and Liquor (pulp and paper), Cooling Water (power), Plating, Galvanizing and Other Coatings, Crude, Product and CO2 Pipeline, Desalination

- Industries:

Power Generation, Chemical Processing, Mining, Water Treatment, Primary Metals, Pulp and Paper, Oil and Gas - Standards:

API682, API610

Low flow, high head design provides smooth and stable operation outside the preferred operating region specified by ISO 13709.API 610.

High-efficiency, radial blade impeller provides better hydraulic fit for low flow applications and continuously rising performance curve.

Replaceable volute inserts are custom machined for each application to give best efficiency point fit for any given set of hydraulics.

Raised Face Flanges are to ASME B16.5 criteria for Class 300 or 600. Surface finish meets API 610 standard. ISO and JIS flanges are available.

ISO 21049/API 682 seal chamber accommodates multiple seal types.

Fully interchangeable with HPX bearing assembly and mechanical seals.

Operating Parameters

- Flows to 30 m3/h (130 gpm)

- Heads to 280 m (920 ft)

- Pressures to 80 bar (1160 psi)

- Temperatures from -160°C (-250°F) to 450°C (840°F)

Dealing with high head and limited flow rates? The HPXM pump is optimized for efficiency and reliability where it matters most. Reach out today and we’ll help size the perfect HPXM unit for your toughest applications.