MP1 Multiphase Screw Pump

MP1 Multiphase Screw Pump

MP1 Multiphase Screw Pump

| Brand: | Flowserve |

|---|---|

| Description: |

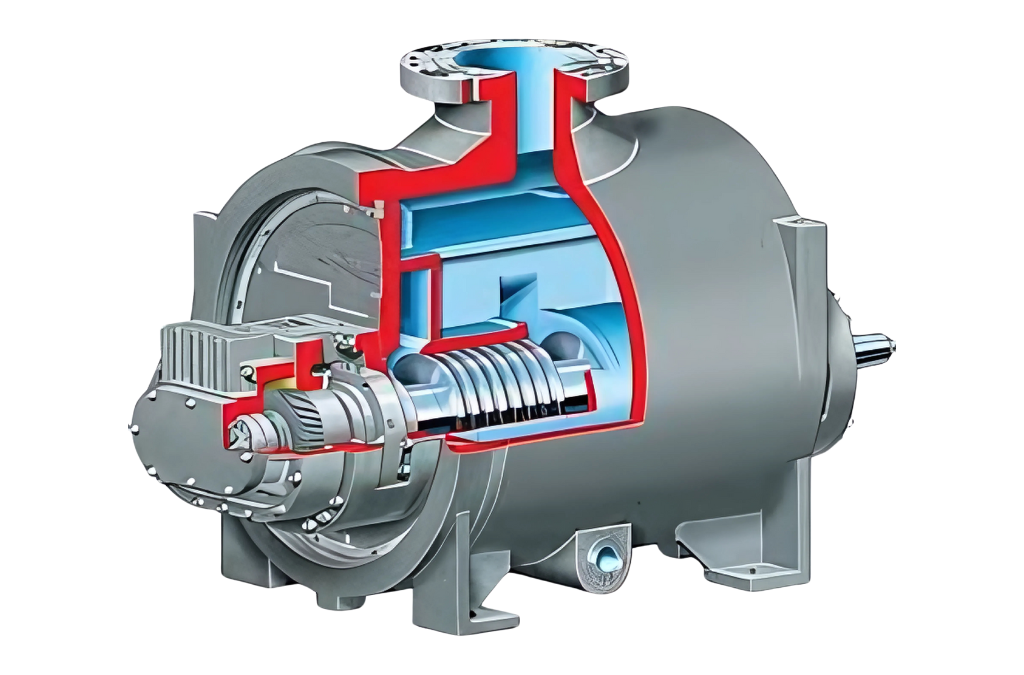

The MP1 Multiphase Screw Pump is a twin-screw positive displacement pump designed to transport crude oil gas water and solid mixtures in upstream oil and gas production. Capable of handling high gas volume fractions without separation, the MP1 is ideal for multiphase boosting gathering lines and wet gas compression in remote or unmanned operations. The pump’s axially balanced screw design ensures smooth pulsation-free flow while maintaining consistent volumetric efficiency across a wide range of flow conditions. With excellent suction capability and the ability to tolerate entrained solids, the MP1 eliminates the need for phase separation upstream, reducing infrastructure cost and complexity. Built to API 676 standards and available in a variety of metallurgies, the MP1 offers reliable long-term performance in harsh production environments including onshore offshore and FPSO platforms. |

The Flowserve MP1 multiphase pump is engineered for the challenges of today’s industry. It is designed for high-viscosity, high flow, low NPSH applications. Highly reliable in tough services, the MP1 is able to handle slurries to 70% solids by weight and multiphase applications to 100% gas void fractions.

MP1 Multiphase Screw Pump Applications

Crude, Product and CO2 Pipeline, Drilling and Production

- Industries:

Oil and Gas

Key features

-

Twin-screw positive displacement design, axially balanced for low pulsation and high volumetric efficiency.

-

Handles gas volume fractions 0%–100% GVF without separation.

-

Tolerant of entrained solids, slurries up to 70% solids by weight.

-

Built to API-676 standards; modular, non-welded casing available in multiple alloys.

-

External bearings and AGMA-11 timing gears in separate oil reservoirs (protected from pumped fluid).

-

Versatile ISO 21049 / API 682 seal chamber; split bearing bracket for easy maintenance.

-

Nozzles integral to outer casing to isolate piping loads and maintain non-contacting shaft design.

Operating Parameters

- Flows to 1990 m3/h (8750 gpm)

- Pressure to 50 bar (720 psi)

- Temperatures to 450°C (850°F)

- Viscosities to 8000 cp

- Gas volume fractions from 0% to 100%

- Shaft tip speeds to 30 m/s (100 ft/s)

FAQ

-

Q: Can the MP1 pump crude oil gas water and solids without upstream separation?

A: Yes. The MP1 is designed for multiphase streams and can operate with 0 to 100 percent gas volume fraction and entrained solids reducing the need for phase separation. Final suitability depends on particle size and system design so consult performance data. -

Q: Is the MP1 suitable for dewatering and multiphase boosting applications?

A: Yes. MP1 is commonly used for dewatering and multiphase boosting where continuous flow without separators is required. Verify suitability with performance curves and the specific inlet conditions. -

Q: Can the MP1 be used for oil transfer in pipelines?

A: Yes. The MP1 can deliver up to 1,990 m3 per hour and pressures up to 50 bar making it suitable for crude transfer pipeline boosting and product transfer. Always verify sizing with pump performance curves and consult an engineer for final application confirmation.

Oil & Gas Pumps Upstream and Pipeline

Boost oilfield production with the MP1 Multiphase Screw Pump designed for efficient transport of unprocessed well stream fluids. Contact us today for performance data or system integration support