Flowserve DVSR Between Bearings Pump

Flowserve DVSR Between Bearings Pump

Flowserve DVSR Between Bearings Pump

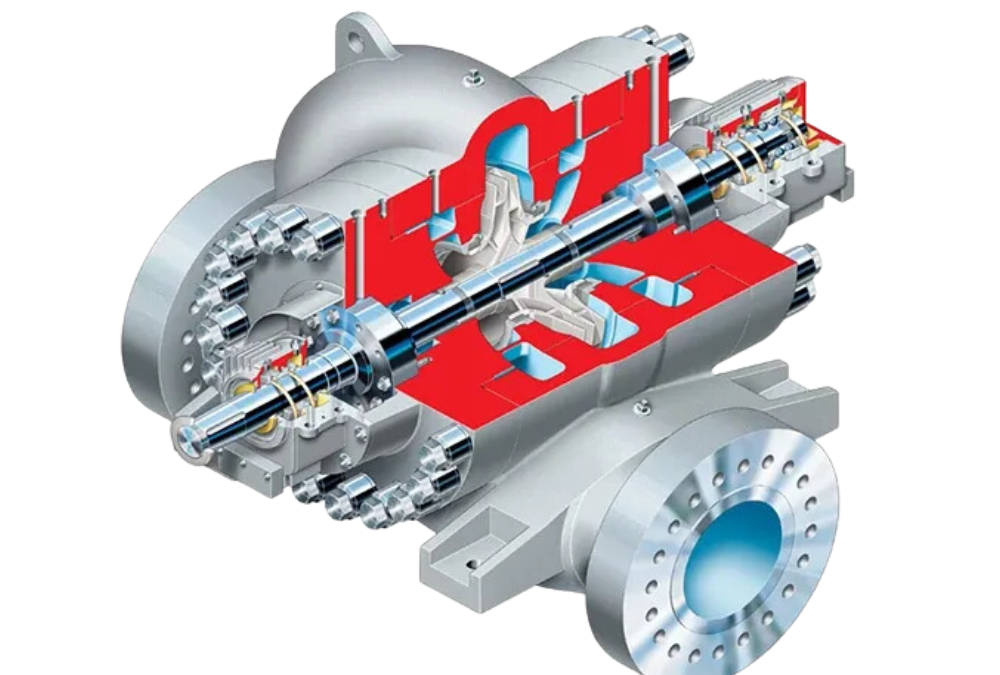

The Flowserve DVSR pump is a horizontally split, multistage, between bearings centrifugal pump engineered for high-pressure fluid transfer in critical industrial applications. Designed to meet demanding performance requirements, the DVSR delivers reliable operation in high head, high flow systems such as boiler feed, condensate transfer, reverse osmosis, and water injection services.

With its between-bearings design, the DVSR ensures superior rotor stability, extended bearing life, and smooth operation under high differential pressures. The pump features a modular construction for ease of maintenance and is available in a variety of metallurgies for compatibility with aggressive fluids and elevated temperatures.

Compliant with major international standards, the Flowserve DVSR is a preferred choice across power generation, oil & gas, petrochemical, and industrial water treatment sectors.

Flowserve DVSR Between Bearings Pump Application\

- Power

- Nuclear

- Conventional Steam

- Combined Cycle

- Concentrated Solar Power (CSP)

- Biomass & MSW

- Geothermal

- Chemicals

- Basic (Organic & Inorganic)

- Water

- Water Management

- Flood Control System

- Oil & Gas

- Upstream Exploration & Production

- Midstream Transportation

- Downstream Processing

- General Industries

- Other Industries

- Mining

DVSR Between Bearings Pump Features

- Radially split cases can operate at far lower specific gravities and much higher pressures than comparable axially split cases.

- Sucker and Discharge Nozzles are integrally cast in casing, allowing pumps to be disassembled without disrupting the piping.

- The Double Volute Design lowers hydraulic radial forces in all circumstances, even at the lowest flow.

- Double Suction: The impeller provides low NPSHr and hydraulic axial balance.

- ISO 10549 / API 682 Seal Chambers accommodate a wide range of seal configurations while ensuring adequate flow around the seal faces.

- Under the first critical speed, the heavy-duty shaft construction ensures trouble-free operation.

- Standard renewable casing and impeller wear rings provide hydraulic stability and high operating efficiency.

Technical Data

ISO 13709 / API 610 Hydraulic Institute

- Flows to 3635 m3/h (16000 gpm)

- Heads to 250 m (820 ft)

- Pressures to 260 bar (3750 psi)

- Temperatures to 204°C (400°F)

- Speeds to 4000 rpm

Size Range: Sizes from 150 mm (6 in) to 600 mm (24 in)

DVSH Heavy-Duty, Between Bearings, Axially Split, Single-Stage, Double-Suction Pump – Brochure