Alfa Laval Koltek Shutter Valve

Alfa laval’s shutter valves are suitable in applications with large products, high viscous or strict requirements minimizing pressure loss. The shutter valve range is designed for use in the food, chemical, pharmaceutical and other industries with high hygiene requirements.

Alfa Laval Valve Automations: Indication Unit, IndiTop, ThinkTop, ThinkTop Basic, ThinkTop D30, GreenTop

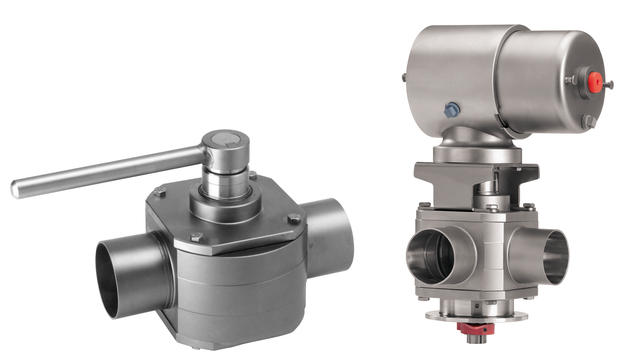

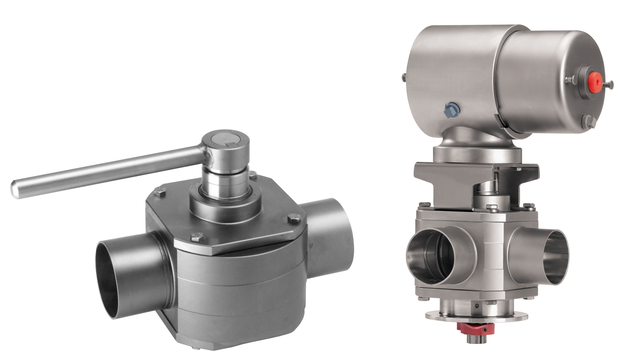

Alfa Laval Koltek Shutter Valve

The Alfa Laval Koltek Shutter Valve is a manually or pneumatically operated shutter valve designed for hygienic applications in the food, chemical, pharmaceutical and biotech industries. It is particularly suitable for high-viscosity products, large particle sizes or processes with strict pressure-loss requirements.

Koltek valves offer reliable shut-off while maintaining hygiene, making them ideal for sensitive production lines. Available in 2-way or 3-way configurations, the Koltek shutter valve can be fitted with manual handles or pneumatic actuators.

Related Industries: Processed Foods, Home & Personal Care, Pharmaceutical, Biotech, Chemical

Models

-

2-Way

-

3-Way

-

Manual

-

Air Actuated

Alfa Laval Koltek Shutter Valve Application

-

Designed for products with large particles or viscous fluids.

-

Minimizes pressure loss in demanding processing conditions.

-

Available in manual and pneumatically operated versions.

-

PTFE shutter ensures reliable sealing and hygiene.

-

Can be integrated with Alfa Laval valve automation units: Indication Unit, IndiTop, ThinkTop, ThinkTop Basic, ThinkTop D30 and GreenTop.

Standard Design

-

Rigid stainless steel body with internal cylindrical bore.

-

2 or 3 ports for pipe connection.

-

Shutter shaft supported and positioned by guide rings.

-

Pneumatic actuators designed with rack and pinion mechanism, insensitive to pressure shocks.

-

Welding ends as standard for sanitary applications.

MH52 with handle

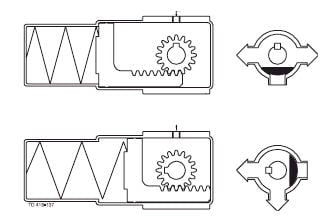

Working principle

A PTFE shutter is operated via handle or actuator. A spring system presses the shutter tightly against the valve body’s cylindrical surface to ensure full sealing.

-

Manual version: Operated with a stainless steel handle, optional lateral indication unit.

-

Pneumatic version: Operated with single-acting (spring return) or double-acting (air-to-air) actuators. Can be fitted with ThinkTop® or lateral indication units for remote monitoring.

Single acting actuator

This design provides tight shut-off, simple maintenance, and compatibility with CIP cleaning systems when pulsed correctly.

WORKING PRINCIPLE

A PTFE shutter is operated by means of a handle or an actuator. A spring washer system presses the shutter against the internal cylindrical surface of the valve body, ensuring a tight seal.

The air-actuated valve can be fitted with top units or a laterally fitted indication unit for remote indication of the valve position. The manually operated valve can be fitted with laterally mounted indication units. The actuators are a rack and pinion design available in spring return or air-to-air versions. The spring return actuator operates with one main piston, while the air-to-air actuator operates with two.

STANDARD DESIGN

The valve consists of a rigid body with an internal cylindrical bore and two or three ports for pipe line connection. The two lids have guide rings or bearings for an internal shaft, which supports and positions the shutter. The stainless steel handle or actuator is fitted to turn the shaft.

The actuator consists of a system of cylinders and one or two main pistons interconnected with a toothed bar (rack and pinion), which interacts with a gear wheel on the valve shaft. The system is insensitive to pressure shocks in the valve.

Certain industries require disassembly and cleaning of the manually operated versions of the valve. Pneumatically operated versions of the valve do not need to be disassembled to ensure proper cleaning, if correctly controlled (pulsed) during the cleaning operation.

To achieve total drainability, the manual or pneumatically operated version of the valve should be installed in the piping system with at least one port in the vertical downward position.

MATERIALS

| Product Wetted Steel Parts | 316L |

| Finish | Polished |

| Seals | Shutter in PTFE |

| Seals (in valve) | EPDM rubber |

| Seals (in actuator) | Nitrile (NBR) |

TECHNICAL DATA

| Max Temperature | 230°F |

| Max Pressure Against Shutter | 44 psi |

| Max Pressure Behind Shutter | 145 psi |

| Air Pressure for Actuator | 116 psi (max) |

| Compressed Air Connection | R 1/8″ (BSP), internal thread |

FAQ

Q1: What is a shutter valve?

A shutter valve is a hygienic shut-off valve that uses a PTFE shutter pressed against the valve body to ensure complete sealing. It is ideal for viscous or particle-rich products where pressure loss must be minimized.

Q2: What is the Alfa Laval Koltek Valve used for?

The Alfa Laval Koltek Shutter Valve is used in food, chemical, pharmaceutical, and biotech industries for handling products with strict hygiene requirements. Common applications include viscous product shut-off, utility processing, and CIP systems.

Q3: How does a shutter valve function?

The shutter valve operates by pressing a PTFE shutter tightly against the valve body. This can be done manually with a handle or pneumatically using an actuator. The mechanism ensures reliable shut-off without product contamination.

Q4: What types of actuators are available for shutter valves?

Shutter valves can be fitted with single-acting (spring return) or double-acting (air-to-air) actuators. They are also compatible with Alfa Laval ThinkTop® automation units for position monitoring.

Q5: What is the difference between manual and air-actuated shutter valves?

Manual shutter valves are controlled by a handle, suitable for simpler operations. Air-actuated shutter valves use compressed air with rack and pinion actuators, allowing remote operation and integration with process automation.