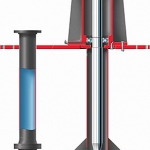

MJC Overhung, Vertical Cantilever, Rubber Lined Slurry Pump

The Worthington MJC Overhung, Vertical Cantilever, Rubber Lined Slurry Pump is purpose-built for sump and tank applications where abrasive, corrosive slurries are present. Its cantilever design eliminates submerged bearings and seals, making it an ideal choice for vertical sump service in mining, mineral processing, wastewater and chemical industries. With its rubber lined liquid end and robust construction, the MJC pump provides superior abrasion and corrosion resistance, ensuring long service life in the toughest environments. The type MJC hard metal slurry pump is a true stiff-shaft cantilever design, without bottom bearings and requiring no flushing water. The MJC is particularly well suited for applications in which flushing liquids are not available or cannot be tolerated. Sump Service, Slurries, Pulp and Paper, Wet Pit, Mining, Dry Pit, Mineral Processing Hard Metal Casing made from abrasion and corrosion resistant high chrome iron incorporates integrally cast straightening vanes in the suction nozzle to reduce pipe swirl and extend impeller life. Closed Impeller includes pump-out vanes on front and rear shroud to reduce stuffing box pressure and suction recirculation as well as balance axial hydraulic loads. Standard Packing Type Stuffing Box is protected by replaceable wear plate and is drilled and tapped for L5 and 2L3 lantern ring positions. Provided with full and low flow flush connections. Optional 316 SS, Alloy 20 or Alloy C-276 materials. Cantilever design – no submerged bearings or seals required Rubber lined slurry pump construction for maximum resistance to abrasion and corrosion Closed impeller with pump-out vanes – reduces stuffing box pressure and recirculation Heavy-duty bearing frame – designed for belt or direct drive loads Stuffing box options – acid-resistant kits, mechanical seals, or hard metal expellers Interchangeability of parts – shared components with R and M series pumps The MJC vertical sump pump is ideal for: Mining & mineral processing – sump service, slurry transfer, dewatering Wastewater treatment & collection systems Pulp and paper wet pits Chemical processing slurries Dry pit and wet pit applications requiring corrosion and abrasion resistance This makes the MJC one of the most reliable choices for anyone searching for vertical cantilever sump pumps or rubber lined slurry pumps. Operating parameters Why Choose the MJC Rubber Lined Sump Pump? No need for flushing water in sump service Superior wear resistance in abrasive and corrosive slurry conditions Long service life with rubber lined and hard metal options Reduced downtime thanks to easily replaceable parts Proven reliability in mining, wastewater, and chemical industries FAQs Q: What is a vertical cantilever sump pump? Q: Why choose a rubber lined slurry pump? Q: What industries use the MJC slurry pump? Type M Hard Metal Abrasive Slurry Pump Bulletin Need reliable sump pumping for corrosive and abrasive slurries? The MJC pump provides long-lasting performance with rubber lining and cantilever simplicity. Let’s match your application with the right MJC model today. MJC Overhung, Vertical Cantilever, Rubber Lined Slurry Pump

MJC Overhung, Vertical Cantilever, Rubber Lined Slurry Pump

Brand:

Worthington

Description:

MJC Slurry Pump Application

Wastewater Collection and Treatment, Water Treatment, Slurry Transfer, Slurry ProcessingKey Features of the MJC Vertical Cantilever Pump

Applications – Vertical Sump Pump Service

A vertical cantilever sump pump is designed without submerged bearings or seals, making it ideal for abrasive slurry sump applications where flushing liquids are not available.

Rubber lining provides excellent resistance to corrosion and abrasion, extending pump life in aggressive slurries.

It is widely used in mining, mineral processing, wastewater treatment, pulp & paper, and chemical plants.